JBS motor powered concrete mixing pump is a new type of equipment that integrates the functions of a concrete mixer truck and a concrete trailer pump. It adopts a fully hydraulic pumping system and has the characteristics of large concrete pouring volume, stable performance, small size, and small operating space. It is suitable for small and medium-sized house buildings with a height of 2 meters to 100 meters, as well as various projects such as mine caves, highway and railway tunnels, water conservancy and hydropower projects, and geological disaster slope protection.

The structure of motor powered concrete mixing pump

JBS electric concrete mixer pump is a new type of equipment that integrates the functions of concrete mixer truck and concrete trailer pump. It is mainly composed of mixing system, pumping system, hydraulic oil pump, lubrication system, control system, motor, mobile frame, concrete pipe and accessories.

Working principle of motor powered concrete mixing pump

The batching machine transports the proportioned materials to the mixer for mixing, and the mixed concrete is transported to the trailer pump. When the trailer pump is started, the concrete enters the injection port through the hopper and is pressed backward by the screw conveyor on the volumetric hopper. At the same time, under the action of the concrete conveying cylinder, the concrete is pressed into the outlet pipe, and the pressure difference is quickly used to form pumping, realizing the transportation from the mixing station to the construction site.

Common types of motor powered concrete mixing pump

JBS30 elctric motor concrete mixing pump

JBS30 electric concrete mixing pump is an integrated equipment for concrete mixing and pumping with a processing capacity of up to 30m³ per hour. The pumping height can reach 2 meters to 100 meters, and the on-site operation is convenient and fast.

| Model | JBS30 |

| Capacity(m³/h) | 30 |

| Motor engine power(kw) | 37 |

| Overall weight(kg) | 5000 |

JBS40 elctric motor concrete mixing pump

JBS40 electric concrete mixing pump is an integrated equipment for concrete mixing and pumping with a processing capacity of up to 40m³ per hour. The pumping height can reach 2 meters to 100 meters, and the on-site operation is convenient and fast.

| Model | JBS40 |

| Capacity(m³/h) | 40 |

| Motor engine power(kw) | 45 |

| Overall weight(kg) | 5500 |

Advantages of motor powered concrete mixing pump

1.Adopt open hydraulic system, stable and reliable performance, low failure rate

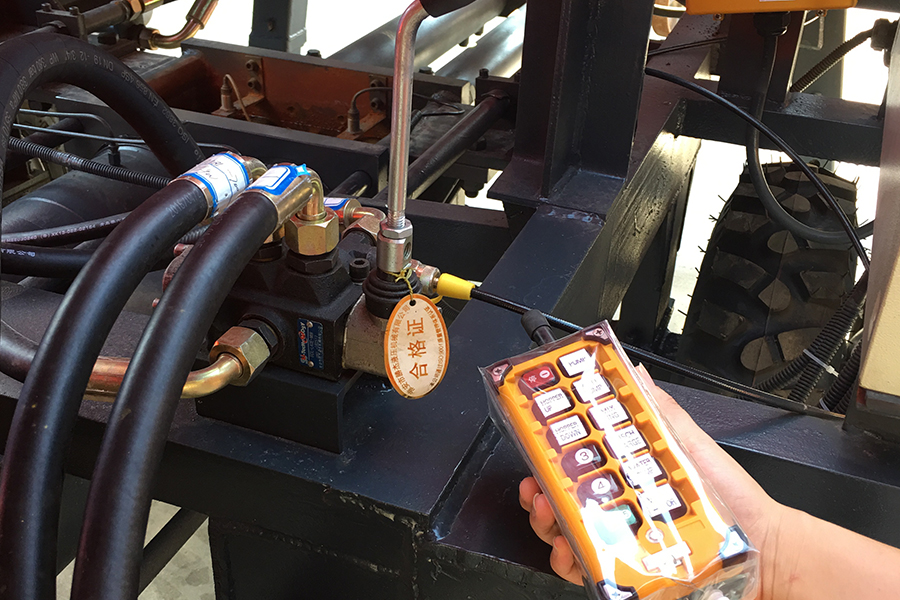

2.Integrated control of mixing and pumping, wireless remote control, easy operation.

3.The concrete mixer adopts wear-resistant alloy material to extend service life

4.Main oil pump. Adopt domestic well-known brand Kawasaki series.

5.Lubrication system. Adopt automatic lubrication system, high oil pressure and stable lubrication effect.

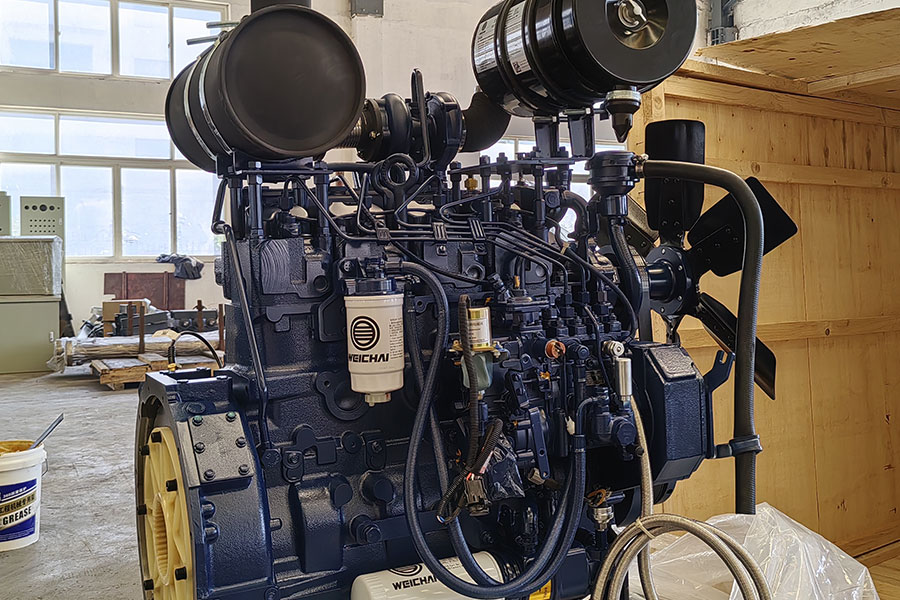

6.Power system. Adopt domestic and foreign well-known brand motor or diesel engine.

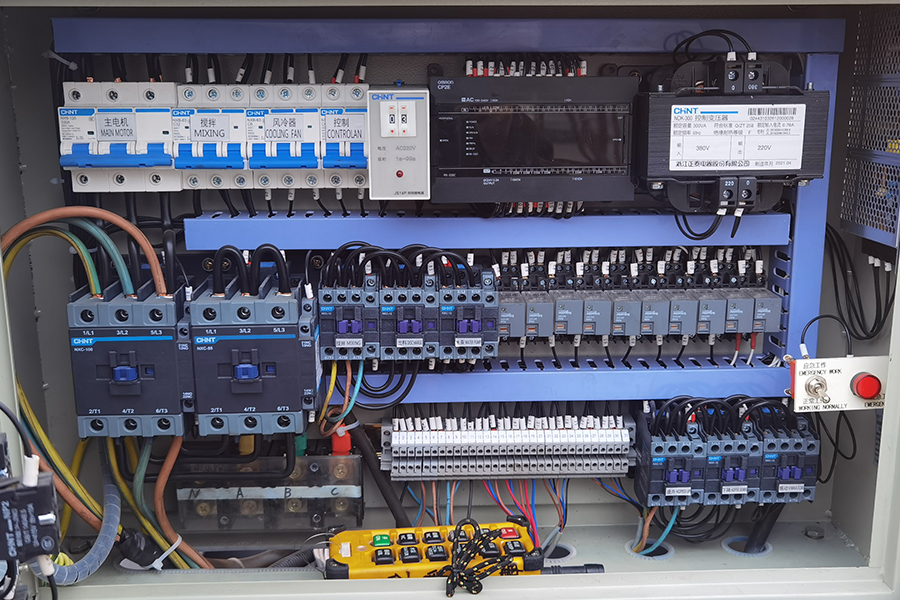

7.Control system. Adopt Japanese Omron PLC control system, equipped with wireless remote control, more flexible and convenient operation.

8.S valve adopt wear-resistant cast iron material, with the advantages of high pressure resistance and wear resistance.

9.Concrete piston. Adopt imported materials for precision processing, with the characteristics of hydraulic resistance, wear resistance and high temperature resistance.

Delivery of motor powered concrete mixing pump

More details on the motor powered concrete mixing pump

Each concrete pump includes 100/150m concrete pipe and accessories (clamps, rubber, cleaning balls, etc.)

The control system adopts local and remote control, Siemens/Omron PLC, Schneider/CHNT electrical components, and the voltage can be customized.

The main hydraulic pump adopts Kawasaki brand to ensure the quality of concrete pump.

The world-famous brands Cummins/Weichai Deutz/Weifang are adopted.

The hydraulic valve adopts Huade brand.

Mixing and pumping can be carried out at the same time.

It can pump self-mixed concrete and commercial concrete.

Parameters of motor powered concrete mixing pump

| Model | JBS30 | JBS40 |

| Theoretical capacity(m³/h) | 30 | 40 |

| Max. concrete pumping pressure(Mpa) | 10 | 10 |

| Power type | Motor | Motor |

| Main electric motor(kw) | 37 | 45 |

| Main oil pump | Kawasaki | Kawasaki |

| Main oil pump capacity(ml/min) | 71 | 112 |

| Theoretical delivery distance(m) | 120/350 | 160/500 |

| Hopper capacity(L) | 550 | 550 |

| Max. aggregate diameter(mm) | 20/30 | 30/40 |

| Inside diameter of delivery pipe(mm) | 125 | 150 |

| Loading capacity of the mixer(L) | 560 | 720 |

| Unloading capacity of the mixer(L) | 350 | 450 |

| Mixing motor(kw) | 5.5 | 5.5 |

| Hoisting motor(kw) | 4.5 | 4.5 |

| Dimension(LxWxH)(mm) | 4500x2200x2800 | 4800x2200x2800 |

| Total weight(kg) | 5000 | 5500 |

Other concrete production equipment

Motor powered concrete mixing pump price

Henan Hengyuan has been established for 25 years. As a professional concrete batching plant manufacturer, we have a professional technical team and production team, and can provide you with high-quality concrete mixing pump equipment. All equipment is produced by our factory, and the price is the factory price.

For the specific price of the concrete mixing pump, you can leave your contact information and production requirements. We will design the most suitable solution for you according to your actual site and production requirements, and provide the most favorable price.