The mobile stabilized soil mixing plant is a product further developed on the basis of the combined detachable stabilized soil mixing station. The whole set of equipment adopts a twin-horizontal shaft mixing form, which can mix quicklime, slaked lime, earth, sand and gravel, fly ash, cement and other materials into stabilized soil.

The structure of mobile stabilized soil mixing plant

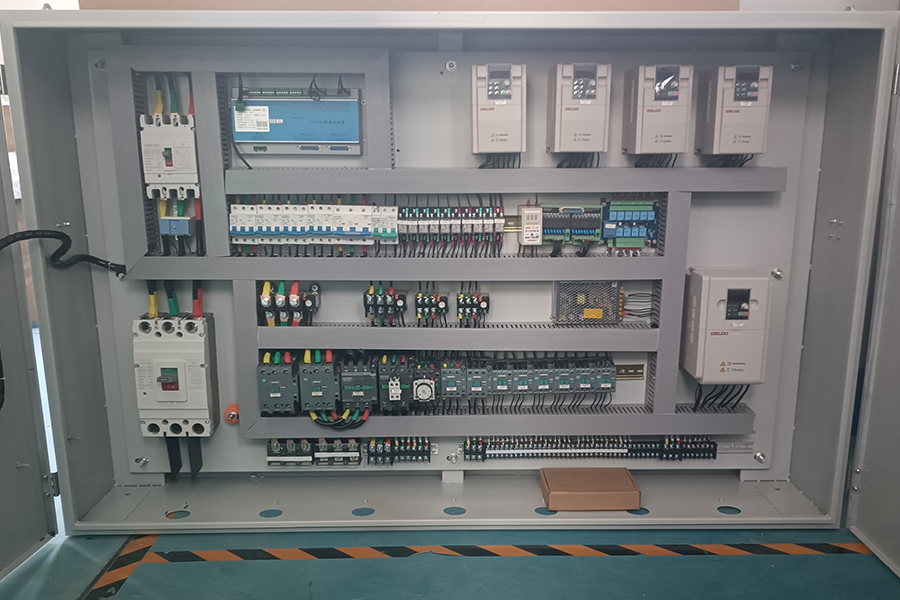

The mobile stabilized soil mixing plant is mainly composed of a mixing system, a batching system, a conveying system, a control system, a mobile frame and a cement silo. The mixing system generally adopts a double horizontal shaft forced continuous pushing mixing method, the batching system adopts a flat belt conveyor, the frequency conversion control weighing accuracy, the conveying system adopts a small angle belt conveyor, the control system adopts a fully automatic control module, which is stable and safe, and the mobile frame adopts a steel structure, which is stable and safe.

Working principle of mobile stabilized soil mixing plant

The material is transported to the stabilized soil hopper by the loader, automatically weighed by the electronic belt scale and screw conveyor and transported to the mixer for mixing. An appropriate amount of water is added during the mixing process for mixing. The finished material falls onto the inclined belt conveyor through the discharge port and is then transported to the storage bin and waits for loading.

Common types of mobile stabilized soil mixing plant

WBZ300 stabilized soil mixing plant

WBZ300 mobile stabilized soil mixing station is a stabilized soil mixing equipment with a processing capacity of up to 300m³ per hour and a total power of 88kw, suitable for various stabilized soil mixing sites.

| Model | WBZ300 |

| Capacity(m³/h) | 300 |

| Total Power (kw) | 88 |

| Overall weight(t) | 39 |

WBZ400 stabilized soil mixing plant

WBZ400 mobile stabilized soil mixing station is a stabilized soil mixing equipment with a processing capacity of up to 400m³ per hour and a total power of 105kw, suitable for various stabilized soil mixing sites.

| Model | WBZ400 |

| Capacity(m³/h) | 400 |

| Total Power (kw) | 105 |

| Overall weight(t) | 41 |

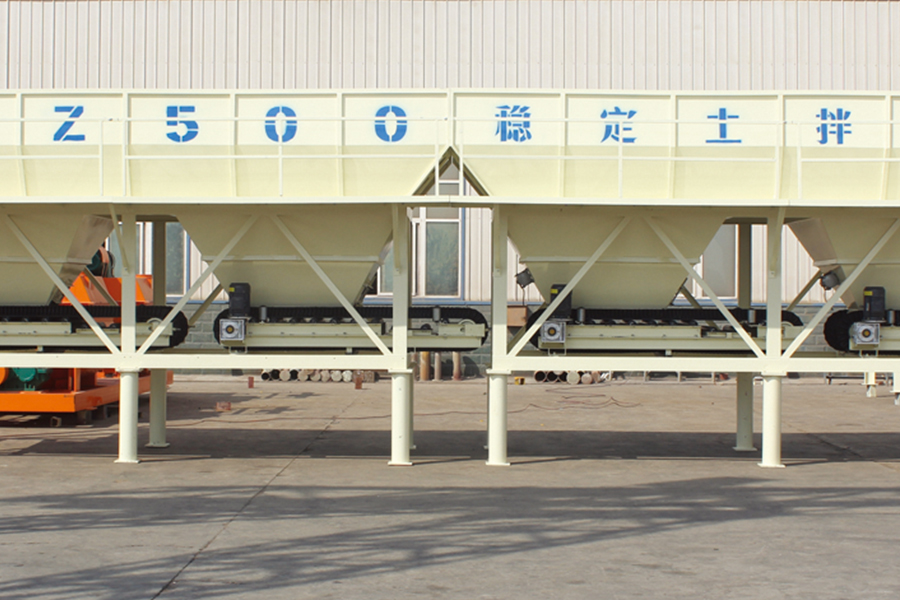

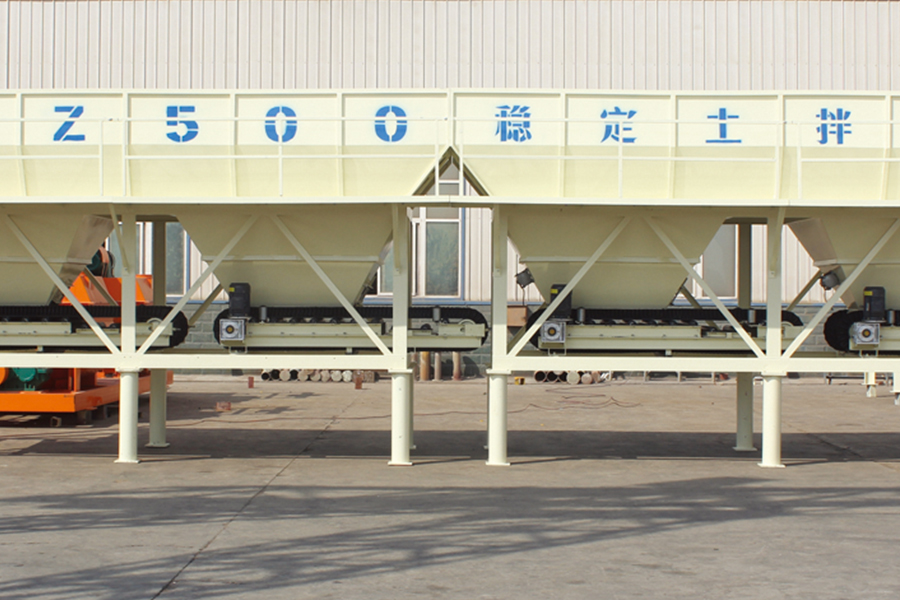

WBZ500 stabilized soil mixing plant

WBZ500 mobile stabilized soil mixing station is a stabilized soil mixing equipment with a processing capacity of up to 500m³ per hour and a total power of 158kw, suitable for various stabilized soil mixing sites.

| Model | WBZ500 |

| Capacity(m³/h) | 500 |

| Total Power (kw) | 158 |

| Overall weight(t) | 50 |

WBZ600 stabilized soil mixing plant

WBZ600 fixed stabilized soil mixing station is a stabilized soil mixing equipment with a processing capacity of up to 600m³ per hour and a total power of 168kw, suitable for various stabilized soil mixing sites.

| Model | WBZ600 |

| Capacity(m³/h) | 600 |

| Total Power (kw) | 168 |

| Overall weight(t) | 54 |

WBZ700 stabilized soil mixing plant

WBZ700 fixed stabilized soil mixing station is a stabilized soil mixing equipment with a processing capacity of up to 700m³ per hour and a total power of 179kw, suitable for various stabilized soil mixing sites.

| Model | WBZ700 |

| Capacity(m³/h) | 700 |

| Total Power (kw) | 179 |

| Overall weight(t) | 63 |

WBZ800 stabilized soil mixing plant

WBZ800 fixed stabilized soil mixing station is a stabilized soil mixing equipment with a processing capacity of up to 800m³ per hour and a total power of 200kw, suitable for various stabilized soil mixing sites.

| Model | WBZ800 |

| Capacity(m³/h) | 800 |

| Total Power (kw) | 200 |

| Overall weight(t) | 72 |

Advantages of mobile stabilized soil mixing plant

1.The transport unit has centralized control system, batching system, mixing, lifting and loading functions, and one-stop use. By simply pulling out or folding, only one truck is needed for transportation.

2.The overall double-horizontal shaft forced mixing main machine is adopted. The machine adopts overall functional design, reasonable layout, accurate measurement, convenient maintenance, simple installation, convenient movement, moderate workstation, uniform mixing and high efficiency.

3.It is suitable for relocation and site construction with long lines, many points and frequent restrictions.

4.Quick and fast installation and debugging, ready to use out of the box, and quick to put into production.

5.The machine installation does not require a special foundation, only a piece of land needs to be compacted, and the equipment investment and production costs are low.

Delivery of mobile stabilized soil mixing plant

More details on the mobile stabilized soil mixing plant

The fixed stabilized soil mixing plant needs to use concrete to lay the foundation and then fix the equipment on it, but the structure is perfect and not limited by the model, so the production capacity is high.

The installation roadbed of the stabilized soil mixing plant should be selected in a wider place to reduce the feeding cycle time of small forklifts. At the same time, it can also make the transportation of finished material trucks convenient, smooth, with good power and no interference.

Parameters of mobile stabilized soil mixing plant

| Model | WBZ300 | WBZ400 | WBZ500 | WBZ600 | WBZ700 | WBZ800 |

| Productivity (t/h) | 300 | 400 | 500 | 600 | 700 | 800 |

| Total Power (kw) | 88 | 105 | 158 | 168 | 179 | 200 |

| Total Weight (t) | 39 | 41 | 50 | 54 | 63 | 72 |

| Measuring Mode | Computer Measuring | |||||

| Speed Regulation Mode | Frequency Control | |||||

| Control Mode | Semi-auto/Full-auto Mode | |||||

| Max. Aggregate Size (mm) | 60 | |||||

| Aggregate Measuring Accuracy (%) | ±2 | |||||

| Powder Measuring Accuracy (%) | ±1 | |||||

| Water Measuring Accuracy (%) | ±1 | |||||

Other concrete production equipment

Mobile stabilized soil mixing plant price

Henan Hengyuan has been established for 25 years. As a professional concrete batching plant manufacturer, we have a professional technical team and production team, and can provide you with high-quality fixed stabilized soil mixing plant equipment. All equipment is produced by our factory, and the price is the factory price.

For the specific price of the fixed stabilized soil mixing plant, you can leave your contact information and production requirements. We will design the most suitable solution for you according to your actual site and production requirements, and provide the most favorable price.