The drum mixer is also called a self-falling double-cone reverse discharging concrete mixer. It mixes in the forward direction and discharges in the reverse direction. It can mix plastic and semi-dry hard concrete. The mixing drum of this machine is driven by a gear ring or a rubber roller friction drive. It has the advantages of reliable transmission, light weight, low energy consumption, compact structure, stable operation, simple operation, good mixing quality, and high production efficiency. It is suitable for general construction sites, roads, bridges, hydropower and other projects and small and medium-sized concrete component plants.

The structure of drum mixer

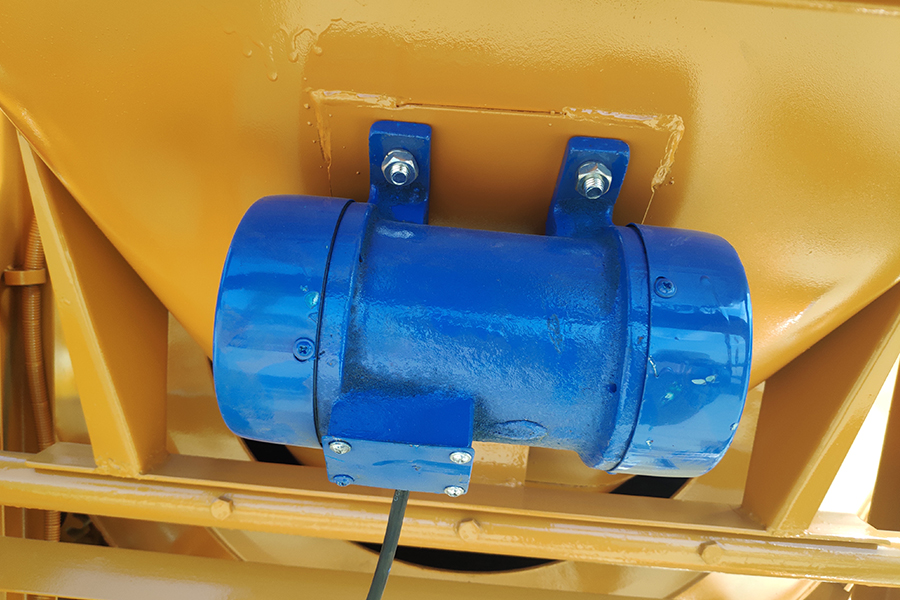

The main components of a drum mixer include a mixing structure, a water supply system, a power mechanism, a transmission system and auxiliary components. The mixing structure is usually composed of a mixing drum, a supporting wheel and a transmission system. The water supply system usually includes a motor, a water pump, a regulating valve, a water suction valve and related pipelines. The power mechanism refers to the part connected to the transmission mechanism through a shaft. The transmission system includes gears and other mechanical parts. Auxiliary components include a feeding frame, a chassis assembly, a reduction system, a clutch, a joystick, a travel wheel, an electrical control box, a cover and a feeding mechanism.

Working principle of drum mixer

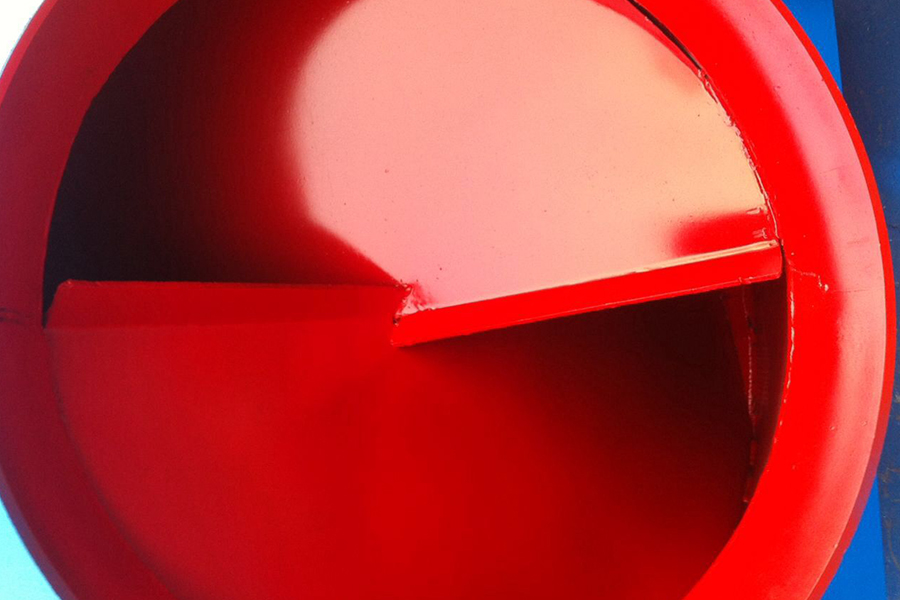

The power mechanism connected to the transmission mechanism through the shaft and the roller driven by the transmission mechanism, the roller body is equipped with a gear ring (or rubber pad) around the roller body, and the transmission shaft is equipped with a gear meshing with the gear ring (or rubber pad).

Put the material to be mixed into the roller and start the equipment. The roller starts to rotate, and the materials are gradually mixed together during the rolling process. While rotating, the roller will also flip to ensure that the materials are evenly distributed inside. When the mixing reaches the predetermined requirements, the discharge port can be opened to discharge the mixed materials.

Common types of drum mixer

JZC250 drum mixer

JZC250 drum mixer is a concrete mixing equipment with a processing capacity of up to 8m³ per hour. The feeding capacity can reach 320L each time and the discharging capacity can reach 250L.

| Model | JZC250 |

| Discharge capacity (L) | 250 |

| Feed capacity (L) | 320 |

| Machine weight (kg) | 1300 |

| Productivity (m³/h) | 6-8 |

JZC350 drum mixer

JZC350 drum mixer is a concrete mixing equipment with a processing capacity of up to 14m³ per hour. The feeding capacity can reach 560L each time and the discharging capacity can reach 350L.

| Model | JZC350 |

| Discharge capacity (L) | 350 |

| Feed capacity (L) | 560 |

| Machine weight (kg) | 1950 |

| Productivity (m³/h) | 10-14 |

JZM350 drum mixer

JZM350 drum mixer is a concrete mixing equipment with a processing capacity of up to 13m³ per hour. The feeding capacity can reach 560L each time and the discharging capacity can reach 350L.

| Model | JZM350 |

| Discharge capacity (L) | 350 |

| Feed capacity (L) | 560 |

| Machine weight (kg) | 1970 |

| Productivity (m³/h) | 13 |

JZC500 drum mixer

JZC500 drum mixer is a concrete mixing equipment with a processing capacity of up to 20m³ per hour. The feeding capacity can reach 800L each time and the discharging capacity can reach 500L.

| Model | JZC500 |

| Discharge capacity (L) | 500 |

| Feed capacity (L) | 800 |

| Machine weight (kg) | 3100 |

| Productivity (m³/h) | 18-20 |

JZM500 drum mixer

JZM500 drum mixer is a concrete mixing equipment with a processing capacity of up to 20m³ per hour. The feeding capacity can reach 800L each time and the discharging capacity can reach 500L.

| Model | JZM500 |

| Discharge capacity (L) | 500 |

| Feed capacity (L) | 800 |

| Machine weight (kg) | 4100 |

| Productivity (m³/h) | 18-20 |

JZC750 drum mixer

JZC750 drum mixer is a concrete mixing equipment with a processing capacity of up to 22m³ per hour. The feeding capacity can reach 1200L each time and the discharging capacity can reach 750L.

| Model | JZC750 |

| Discharge capacity (L) | 750 |

| Feed capacity (L) | 1200 |

| Machine weight (kg) | 4200 |

| Productivity (m³/h) | 20-22 |

JZM750 drum mixer

JZM750 drum mixer is a concrete mixing equipment with a processing capacity of up to 35m³ per hour. The feeding capacity can reach 750L each time and the discharging capacity can reach 1200L.

| Model | JZM750 |

| Discharge capacity (L) | 750 |

| Feed capacity (L) | 1200 |

| Machine weight (kg) | 5500 |

| Productivity (m³/h) | 30-35 |

Advantages of drum mixer

1.Forced mixing method, high-speed mixing, high production efficiency.

2.Wide range of applications, suitable for concrete materials with different proportions.

3.The whole machine has a simple structure and is easy to operate.

4.Adopt wear-resistant and corrosion-resistant materials, easy to maintain and maintain.

5.Good sealing performance and long service life.

6.Automatic control system, saving labor costs.

Delivery of drum mixer

More details on the drum mixer

Drum mixers can be divided into two types according to the transmission mode: JZC (gear ring transmission) and JZM (friction transmission).

Among them, the friction transmission mode can be divided into JZM (motor power) and JZR (diesel engine power) according to the power.

Parameters of drum mixer

| Model | JZC250 | JZC350 | JZM350 | JZC500 | JZM500 | JZC750 | JZM750 |

| Discharge capacity (L) | 250 | 350 | 350 | 500 | 500 | 750 | 750 |

| Feed capacity (L) | 320 | 560 | 560 | 800 | 800 | 1200 | 120 |

| Productivity (m³/h) | 6-8 | 10-14 | 13 | 18-20 | 18-20 | 20-22 | 30-35 |

| Mixer drum speed (r/min) | 17 | 14 | 15 | 13 | 15 | 13 | 12.26 |

| Maximum aggregate particle size (mm) | 60 | 60 | 60 | 60-80 | 60 | 60-80 | 80 |

| Water supply accuracy | Error≤2% | Error≤2% | Error≤2% | Error≤2% | Error≤2% | Error≤2% | Error≤2% |

| Mixer motor power (kw) | 4 | 5.5 | 5.5 | 11 | 2×5.5 | 15 | 2×7.5 |

| Lifting motor power (kw) | 4 | 4.5 | 4.5 | 5.5 | 5.5 | 7.5 | 7.5 |

| Water pump motor power (kw) | 0.55 | 0.55 | 0.75 | 0.75 | 1.1 | 1.1 | 1.1 |

| Tire specifications | 6.50-16 | 6.50-16 | 6.50-16 | 7.50-16 | 7.00-16 | 7.50-16 | 7.50-16 |

| Maximum towing speed (km/h) | 20 | 20 | 20 | 20 | 20 | 20 | 20 |

| Dimensions (mm) | 2260x1990x2750 | 2766x2140x3000 | 3800x2050x2690 | 5226x2200x5460 | 5710x2350x5050 | 6116x2056x6060 | 6216x2300x6060 |

| Machine weight (kg) | 1300 | 1950 | 1970 | 3100 | 4100 | 4200 | 5500 |

Other concrete production equipment

Drum mixer price

Henan Hengyuan has been established for 25 years. As a professional concrete batching plant manufacturer, we have a professional technical team and production team, and can provide you with high-quality concrete mixer equipment. All equipment is produced by our factory, and the price is the factory price.

For the specific price of the concrete mixer, you can leave your contact information and production requirements. We will design the most suitable solution for you according to your actual site and production requirements, and provide the most favorable price.