Screw conveyor is a machine that uses a motor to drive the screw to rotate and push materials to achieve the purpose of conveying. It is a mechanical transportation equipment that uses the special structure of the spiral blade and the gap between the spiral blade and the fixed spiral groove to continuously convey materials. It can convey horizontally, obliquely or vertically, and has the advantages of simple structure, small cross-sectional area, good sealing, easy operation, easy maintenance, and convenient closed transportation.

The structure of screw conveyor

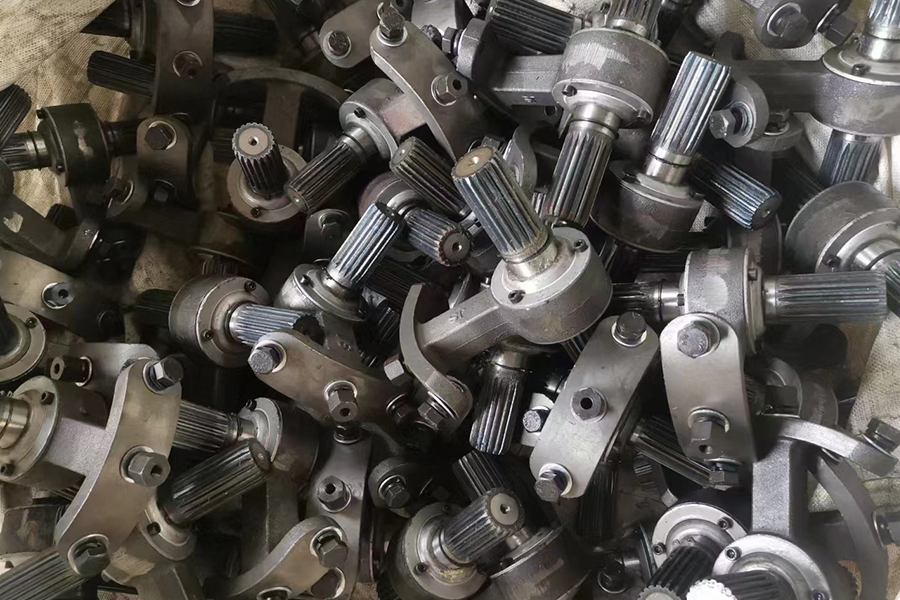

The screw conveyor is mainly composed of a casing, a screw shaft, a transmission device, a feed port, a discharge port, a support frame, a base, a dust cover and related accessories.

Working principle of screw conveyor

When power is turned on, the driver rotates the shaft through the bevel gear, the screw element starts to rotate, the spiral rotates around the shaft and remains in a position close to the bottom of the trough. The material usually enters the screw conveyor from the feed port, and the material will be trapped between the gaps of the spiral blades. As the spiral moves, the material also moves forward along part of the path, transporting the material in the trough from the feed point to the discharge point.

Common types of screw conveyor

LSY160

LSY160 screw conveyor is the most commonly used conveying equipment in concrete batching plants. It has a screw diameter of 160mm and can convey 25t of material per hour. It is suitable for conveying various types of concrete.

| Model | LSY160 |

| Spiral diameter (mm) | 160 |

| Conveying capacity (t/h) | 25 |

| Motor power (kw) | 3-7.5 |

LSY200

LSY200 screw conveyor is the most commonly used conveying equipment in concrete batching plants. It has a screw diameter of 193mm and can convey 35t of material per hour. It is suitable for conveying various types of concrete.

| Model | LSY200 |

| Spiral diameter (mm) | 193 |

| Conveying capacity (t/h) | 35 |

| Motor power (kw) | 4-11 |

LSY250

LSY250 screw conveyor is the most commonly used conveying equipment in concrete batching plants. It has a screw diameter of 250mm and can convey 50t of material per hour. It is suitable for conveying various types of concrete.

| Model | LSY250 |

| Spiral diameter (mm) | 250 |

| Conveying capacity (t/h) | 50 |

| Motor power (kw) | 7.5-15 |

LSY300

LSY300 screw conveyor is the most commonly used conveying equipment in concrete batching plants. It has a screw diameter of 300mm and can convey 75t of material per hour. It is suitable for conveying various types of concrete.

| Model | LSY300 |

| Spiral diameter (mm) | 300 |

| Conveying capacity (t/h) | 75 |

| Motor power (kw) | 11-22 |

Advantages of screw conveyor

1.Simple structure, stable and reliable operation.

2.Wide application range, low pollution.

3.Long service life, low maintenance cost in the later stage.

4.Easy to use, adjustable conveying direction.

Delivery of screw conveyor

More details on the screw conveyor

Screw conveyors of different sizes and lengths can be customized according to actual customer needs.

Parameters of screw conveyor

| Model | LSY160 | LSY200 | LSY250 | LSY300 |

| Spiral diameter (mm) | 160 | 193 | 250 | 300 |

| Conveying length (m) | 2.5-6 | 4.5-12 | 6-9 | 6-9 |

| Spiral speed (r/min) | 100 | 209 | 209 | 174 |

| Shell diameter (mm) | 194 | 219 | 273 | 325 |

| Working angle (°) | ≤20 | ≤45 | ≤45 | ≤45 |

| Conveying capacity (t/h) | 25 | 35 | 50 | 75 |

| Motor model | Y-132M-4 | Y-160M-4 | Y-160L-4 | Y-180L-4 |

| Motor power (kw) | 3-7.5 | 4-11 | 7.5-15 | 11-22 |

Other concrete production equipment

Screw conveyors price

Henan Hengyuan was established 25 years ago. As a professional concrete mixing station manufacturer, we have a professional technical team and production team, and can provide you with high-quality concrete batching plant auxiliary equipment. All equipment is produced by our factory, and the price is the ex-factory price.

For the specific price of the concrete screw conveyor, you can leave your contact information and production requirements. We will design the most suitable solution for you according to your actual site and production requirements, and provide the most favorable price.