Cement silo are generally used for bulk cement storage in concrete mixing plants. They are suitable for storing various bulk building materials such as cement and fly ash. The silo is equipped with a material level system that can display the location and amount of the material. The hole-breaking device can remove the solidity caused by the material being deposited for too long. The mud silo and the screw conveying pump can be used together to transport the material to various locations. The silo is easy to install, safe and reliable, and is an ideal bulk storage tank for various mixing plants.

The structure of cement silos

Cement silo is generally composed of steel structure, ladder, guardrail, feeding pipe, dust collector, pressure safety valve, high and low level gauge, unloading valve and other components.

Working principle of cement silos

When the bulk mud silo is working, it must be erected by a special crane and then placed on a prefabricated concrete foundation. The verticality of the cement silo after it is erected and the horizontal plane must be checked, and then its bottom must be welded firmly to the embedded parts of the foundation.

After the storage silo is fixed, the cement is transported to the construction site by a bulk cement truck, and then the delivery pipeline of the bulk cement truck is connected to the feed pipeline of the cement silo (cement tank), and the cement in the tank is transported to the cement silo (cement tank) through the gas pressure of the bulk cement truck.

In the process of transporting cement to the storage silo, the operator must continuously press the button of the dust collector vibration motor to shake off the cement attached to the dust collector bag to prevent the bag from being blocked and causing a warehouse explosion.

Once the bag is blocked, the pressure in the silo exceeds the safety pressure of the pressure safety valve on the top of the silo, and the pressure safety valve can be opened to release the pressure in the silo to prevent the occurrence of a warehouse explosion accident.

The fullness and lack of material in the silo can be observed by the high and low material levels.

When it is necessary to discharge the material, first open the manual discharge valve at the bottom of the cone, and then convey the cement through the cement conveying device (screw conveyor). During the discharge process, if the “arching” phenomenon occurs, press the button of the solenoid valve of the arch-breaking device in time to blow air to eliminate the “arching” and feed the material to ensure smooth cement supply.

When the cement conveying device (screw conveyor) fails, first close the manual discharge valve at the bottom of the cone to prevent cement from overflowing and causing waste.

Common types of cement silos

SNC30T cement silo

SNC30T is a cement storage equipment, mainly used for cement storage in concrete batching. The silo has a diameter of 2.5 meters and a height of 4.8 meters, and can store 30 tons of cement.

| Model | SNC30T |

| Tank diameter (m) | 2.5 |

| Tank height (m) | 4.8 |

| Capacity (t) | 30 |

SNC50T cement silo

SNC50T is a cement storage equipment, mainly used for cement storage in concrete batching. The silo has a diameter of 3 meters and a height of 5.4 meters, and can store 50 tons of cement.

| Model | SNC50T |

| Tank diameter (m) | 3 |

| Tank height (m) | 5.4 |

| Capacity (t) | 50 |

SNC80T cement silo

SNC80T is a cement storage equipment, mainly used for cement storage in concrete batching. The silo has a diameter of 3 meters and a height of 9 meters, and can store 80 tons of cement.

| Model | SNC80T |

| Tank diameter (m) | 3 |

| Tank height (m) | 9 |

| Capacity (t) | 80 |

SNC100T cement silo

SNC100T is a cement storage equipment, mainly used for cement storage in concrete batching. The silo has a diameter of 3 meters and a height of 11.4 meters, and can store 100 tons of cement.

| Model | SNC100T |

| Tank diameter (m) | 3 |

| Tank height (m) | 11.4 |

| Capacity (t) | 100 |

SNC150T cement silo

SNC150T is a cement storage equipment, mainly used for cement storage in concrete batching. The silo has a diameter of 3 meters and a height of 23.5 meters, and can store 150 tons of cement.

| Model | SNC150T |

| Tank diameter (m) | 3 |

| Tank height (m) | 23.5 |

| Capacity (t) | 150 |

SNC200T cement silo

SNC200T is a cement storage equipment, mainly used for cement storage in concrete batching. The silo has a diameter of 4.5meters and a height of 18.6 meters, and can store 200 tons of cement.

| Model | SNC200T |

| Tank diameter (m) | 4.5 |

| Tank height (m) | 18.6 |

| Capacity (t) | 200 |

SNC300T cement silo

SNC300T is a cement storage equipment, mainly used for cement storage in concrete batching. The silo has a diameter of 4.5 meters and a height of 24.6 meters, and can store 300 tons of cement.

| Model | SNC300T |

| Tank diameter (m) | 4.5 |

| Tank height (m) | 24.6 |

| Capacity (t) | 300 |

SNC500T cement silo

SNC500T is a cement storage equipment, mainly used for cement storage in concrete batching. The silo has a diameter of 6 meters and a height of 22.2 meters, and can store 500 tons of cement.

| Model | SNC500T |

| Tank diameter (m) | 6 |

| Tank height (m) | 22.2 |

| Capacity (t) | 500 |

Advantages of cement silos

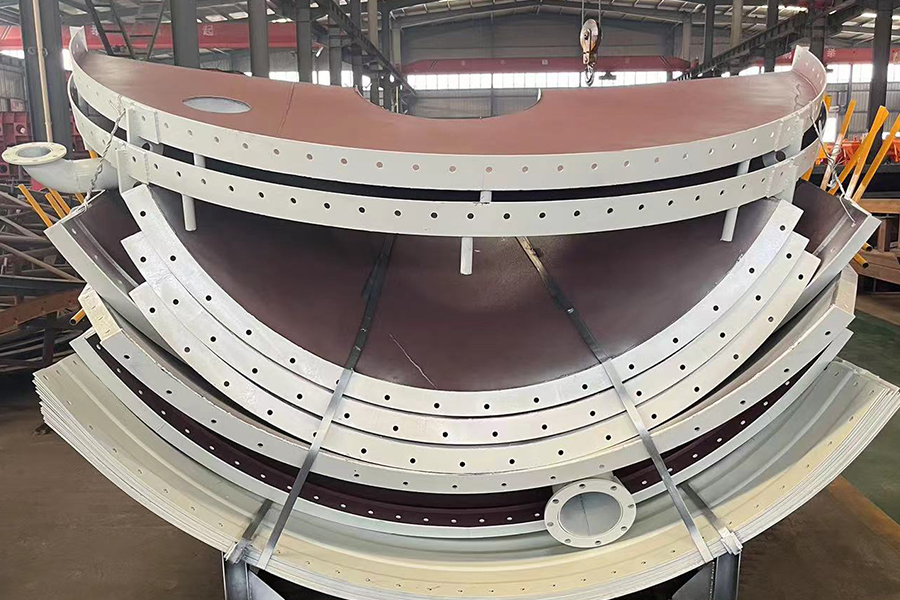

1.Flake design, more convenient disassembly and installation.

2.The warehouse body is made of corrosion-resistant materials and has a long service life.

3.Good sealing effect and no environmental pollution.

4.Large capacity, can be customized according to actual needs.

5.High temperature resistance, explosion resistance, stable and reliable, safe and fireproof.

6.Fully automatic control system, low labor cost.

Delivery of cement silos

More details on the cement silos

The warehouse body adopts a sheet structure, which is better sealed and easier to load into the cabinet than before.

Parameters of cement silo

| Model | Tank diameter (m) | Tank height (m) | Total tank height (m) |

| SNC30T | 2.5 | 4.8 | 11.4 |

| SNC50T | 3 | 5.4 | 12 |

| SNC80T | 3 | 9 | 15.6 |

| SNC100T | 3 | 11.4 | 18 |

| SNC150T | 3 | 23.5 | 29 |

| SNC200T | 4.5 | 18.6 | 25.2 |

| SNC300T | 4.5 | 24.6 | 29.5 |

| SNC500T | 6 | 22.2 | 28.8 |

Other concrete production equipment

Cement silo price

Henan Hengyuan has been established for 25 years. As a professional concrete batching plant manufacturer, we have a professional technical team and production team, and can provide you with high-quality concrete auxiliary equipment. All equipment is produced by our factory, and the price is the factory price.

For the specific price of the concrete auxiliary equipment, you can leave your contact information and production requirements. We will design the most suitable solution for you according to your actual site and production requirements, and provide the most favorable price.