Henan Hengyuan-Manufacturer of various professional construction machinery and equipment

- Conveyor belt type concrete batching plant

- Skip hoist type concrete batching plant

- Dry mix concrete batching plant

- With-foundation concrete batching plant

- Container type concrete batching plant

- YHZM mobile concrete batching plant

- YHZS1.3 mobile concrete batching plant

- YHZS3.8 mobile concrete batching plant

Concrete batching plant auxiliary equipment

What are the concrete batching plant auxiliary equipment?

What is Concrete batching plant auxiliary equipment?What are the auxiliary equipment related to concrete batching plant? Concrete batching plant is a production line equipment used to produce concrete. It can be divided into different types of concrete batching plants according to different production needs. Various machines and equipment are used in the production process, such as concrete batching machine, screw conveyor, cement silo and other auxiliary equipment and various types of mixing hosts. Such as twin-horizontal shaft concrete mixer, drum mixer, vertical shaft planetary mixer, etc.

Customize your concrete batching plant

Concrete batching plant auxiliary equipment-concrete mixer for concrete batching plant

Concrete batching plants can be divided into different types according to the actual needs of customers. Different types of concrete batching stations are used. Common concrete mixers are: twin-shaft concrete mixers, drum mixers, and vertical-shaft planetary mixers.

Twin shaft concrete mixer

Drum mixer

Vertical shaft planetary mixer

Concrete batching plant auxiliary equipment-batching conveying equipment

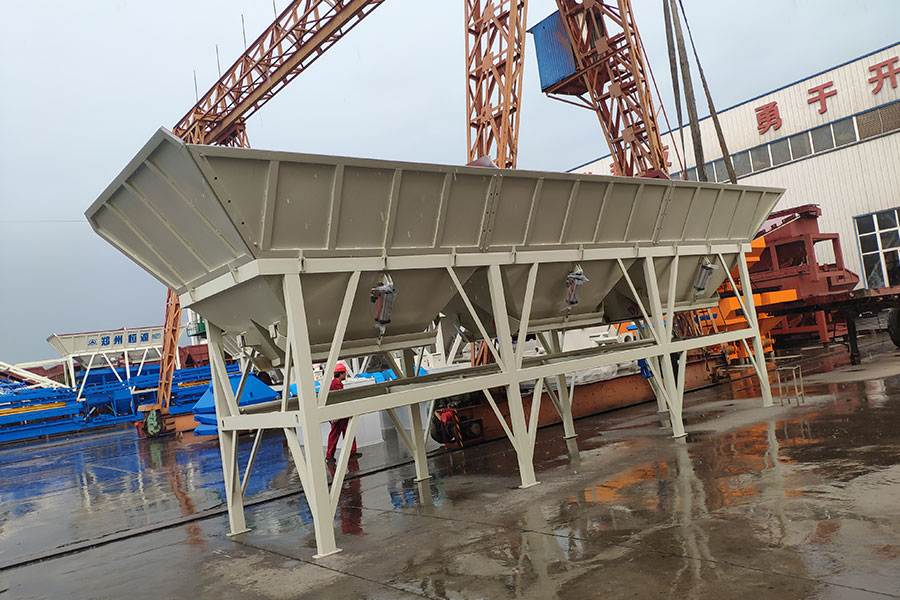

During the operation of the concrete batching plant, the commonly used auxiliary equipment include: concrete batching machine, screw conveyor, cement silo, etc.

Batching Machine

Screw Conveyor

Cement silo

Learn more about concrete batching plant auxiliary equipment?

Other concrete production related equipment

Stationary concrete batching plant is a kind of concrete production equipment with high degree of mechanization and automation, which is widely used in large and medium-sized construction projects, roads, bridge projects and concrete prefabrication plants.

Stationary Concrete Batching Plant

| Model | Capacity(m³/h) | Concrete mixer | Aggregate batching machine(m³) |

| HZS60 | 60 | JS1000 | 4*8 |

| HZS90 | 90 | JS1500 | 4*12 |

| HZS120 | 120 | JS2000 | 4*20 |

| HZS180 | 180 | JS3000 | 4*25 |

| HZS240 | 240 | JS4000 | 4*25 |

| HZS270 | 270 | JS4500 | 4*25 |

The entire set of mobile concrete batching plant equipment adopts an integrated frame, equipped with a JS series twin-shaft mixer, and can work with a concrete pump, making it suitable for mobile operations in various sites.

Mobile Concrete Batching Plant

| Model | Capacity(m³/h) | Type of concrete mixer | Type of batching machine |

| YHZS25 | 25 | JS500 | PLD800 |

| YHZS35 | 35 | JS750 | PLD1200 |

| YHZS50 | 50 | JS1000 | PLD1600 |

| YHZS75 | 75 | JS1500 | PLD2400 |

| YHZS100 | 100 | JS2000 | PLD2400 |

Concrete pump is a kind of concrete pumping and transportation equipment, which is widely used in construction projects such as urban construction, bridge construction, power and other energy facilities. The machine is suitable for areas with stable voltage, has low noise during operation and is easy to move.

Concrete Pump

| Model | Capacity(m³/h) | Motor engine power(kw) | Maximum vertical distance(mm) |

| HBS40 | 40 | 45 | 120 |

| HBS50 | 50 | 55 | 150 |

| HBS60 | 60 | 90 | 200 |

| HBS80 | 80 | 110 | 250 |

| HBS90 | 90 | 110 | 300 |

Concrete mixing pump is a new type of equipment that integrates the functions of concrete mixer truck and concrete trailer pump. It adopts a fully hydraulic pumping system and has the characteristics of large concrete pouring volume, stable performance, small size, and small operating space. It is suitable for small and medium-sized house buildings with a height of 2 meters to 100 meters, as well as various projects such as mine caves, highway and railway tunnels, water conservancy and hydropower projects, and geological disaster slope protection.

Concrete Mixing Pump

| Model | Capacity(m³/h) | Motor engine power(kw) | Total weight(kg) |

| JBS30 | 30 | 37 | 5000 |

| JBS40 | 40 | 45 | 5500 |

| JBTS30 | 30 | 82 | 5000 |

| JBTS40 | 40 | 82 | 5500 |

Stabilized soil mixing station is suitable for the construction of basic materials for expressways, first-class highways, second-class highways, urban roads, airports, stadiums, etc. It can use quicklime, slaked lime, earth, sand and gravel, fly ash, cement and other materials to produce lime-stabilized base materials, cement-stabilized gravel, compacted concrete and other basic materials.

Stabilized Soil Mixing Plant

| Model | Capacity(t/h) | Total Power (kw) | Total Weight (t) |

| WBZ300 | 300 | 88 | 39 |

| WBZ400 | 400 | 105 | 41 |

| WBZ500 | 500 | 158 | 50 |

| WBZ600 | 600 | 168 | 54 |

| WBZ700 | 700 | 179 | 63 |

| WBZ800 | 800 | 200 | 72 |

What can we do for you?

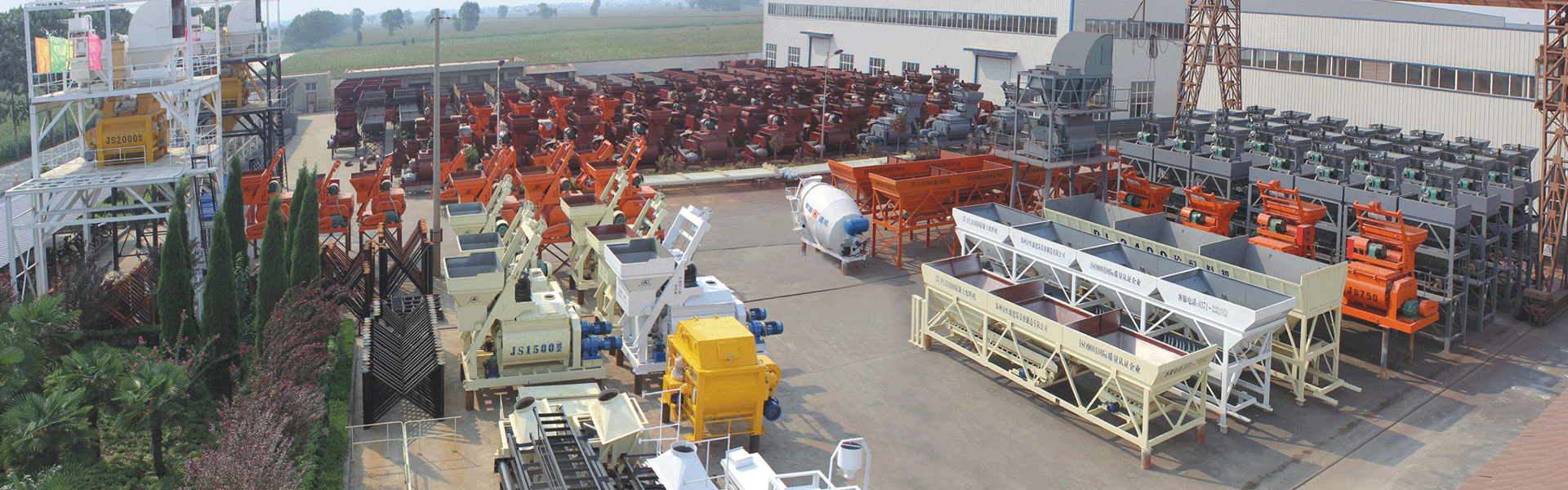

As a professional construction machinery manufacturer, Henan Hengyuan Co., Ltd. not only has a professional technical team, but also has excellent machine quality. At present, the global construction industry is still developing. The concrete mixing plants produced by Henan Hengyuan are often used in large and medium-sized water conservancy, power, bridge and other projects with large concrete engineering volume, long construction period and concentrated construction sites. With the development of municipal construction, the mixing plants that use centralized mixing and provide commercial concrete have great advantages, so they have been rapidly developed, creating conditions for promoting concrete pumping construction and realizing the linkage operation of mixing, conveying and pouring machinery.

1.We will initially select the corresponding machine for you according to your production needs.

2.We will calculate your corresponding site and factory area according to your production requirements and give you factory construction suggestions.

3.After we determine the factory or production line area with you, our professional technical engineers will draw professional installation plans and machine layout drawings for you.

4.If you encounter any problems during the installation of the production line, you can communicate with us at any time. We will send professional installation engineers for video guidance or on-site installation guidance.

5.If you encounter any problems during the production process, just make a phone call and we will help you solve them at any time.