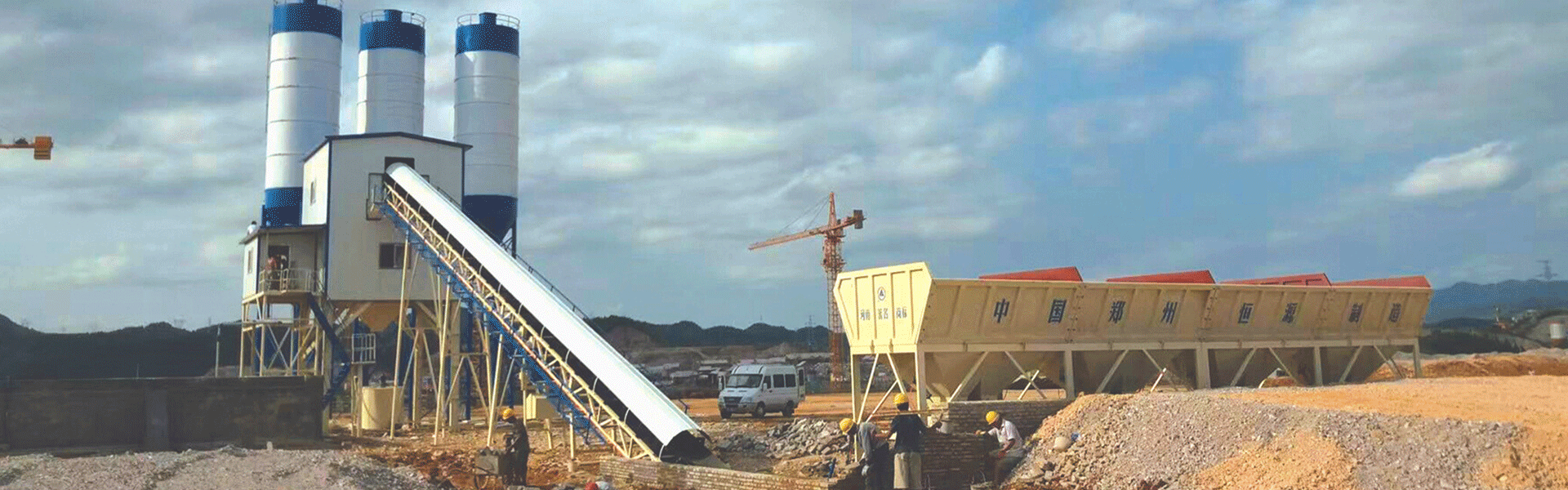

Conveyor belt type concrete batching plant is a kind of concrete production equipment with high degree of mechanization and automation. The concrete batching station adopts belt feeding and precise weighing and mixing technology to ensure the quality of concrete production. It is widely used in large and medium-sized construction projects, roads, bridge projects, concrete prefabrication plants, and is the best choice for commercial concrete suppliers.

The structure of conveyor belt type concrete batching plant

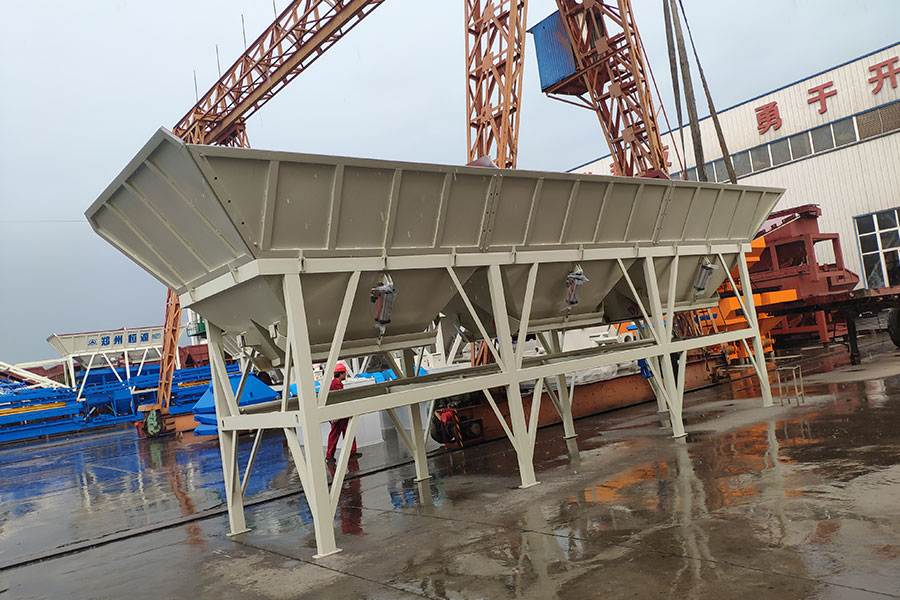

The conveyor belt type concrete batching station is composed of aggregate/fly ash/cement/additive/water batching system, mixing system, conveying system, automatic control system, etc.

Working principle of conveyor belt type concrete batching plant

Raw materials such as cement, sand, aggregates, etc. are put into the batching machine according to a certain ratio. After being accurately weighed and measured by the batching machine, the proportioned materials are transported to the concrete mixer via a belt conveyor. After being mixed evenly by the concrete mixer, they are transported to the mixer truck or concrete pump by a belt conveyor or screw conveyor for on-site construction operations.

Common types of conveyor belt type concrete batching plants

HZS60 conveyor belt type concrete batching plant

HZS60 conveyor belt concrete batching station is a type of belt batching station with a processing capacity of up to 60m³ per hour. It mainly adopts JS1000 twin-shaft mixer and 4.2m discharge height to meet various production scenarios.

| Model | HZS60 |

| Capacity(m³/h) | 60 |

| Concrete mixer | JS1000 |

| Aggregate batching machine(m³) | 4*8 |

HZS90 conveyor belt type concrete batching plant

HZS90 conveyor belt concrete batching station is a type of belt batching station with a processing capacity of up to 90m³ per hour. It mainly adopts JS1500 twin-shaft mixer and 4.2m discharge height to meet various production scenarios.

| Model | HZS90 |

| Capacity(m³/h) | 90 |

| Concrete mixer | JS1500 |

| Aggregate batching machine(m³) | 4*8 |

HZS120 conveyor belt type concrete batching plant

HZS120 conveyor belt concrete batching station is a type of belt batching station with a processing capacity of up to 120m³ per hour. It mainly adopts JS2000 twin-shaft mixer and 4.2m discharge height to meet various production scenarios.

| Model | HZS120 |

| Capacity(m³/h) | 120 |

| Concrete mixer | JS2000 |

| Aggregate batching machine(m³) | 4*8 |

HZS180 conveyor belt type concrete batching plant

HZS180 conveyor belt concrete batching station is a type of belt batching station with a processing capacity of up to 180m³ per hour. It mainly adopts JS3000 twin-shaft mixer and 4.2m discharge height to meet various production scenarios.

| Model | HZS180 |

| Capacity(m³/h) | 180 |

| Concrete mixer | JS3000 |

| Aggregate batching machine(m³) | 4*8 |

HZS240 conveyor belt type concrete batching plant

HZS240 conveyor belt concrete batching station is a type of belt batching station with a processing capacity of up to 240m³ per hour. It mainly adopts JS4000 twin-shaft mixer and 4.2m discharge height to meet various production scenarios.

| Model | HZS240 |

| Capacity(m³/h) | 240 |

| Concrete mixer | JS4000 |

| Aggregate batching machine(m³) | 4*8 |

HZS270 conveyor belt type concrete batching plant

HZS270 conveyor belt concrete batching station is a type of belt batching station with a processing capacity of up to 270m³ per hour. It mainly adopts JS4500 twin-shaft mixer and 4.2m discharge height to meet various production scenarios.

| Model | HZS270 |

| Capacity(m³/h) | 270 |

| Concrete mixer | JS4500 |

| Aggregate batching machine(m³) | 4*8 |

Advantages of conveyor belt type concrete batching plant

1.Fully automatic control system, PLC adopts Siemens brand, and main electrical components adopt Schneider/CHNT brand.

2.Control panel and system language can be customized.

3.Mixing system uses JS/SICOMA twin-shaft concrete mixer, which has high efficiency and high mixing quality.

4.Aggregate batching machine loading height can be customized (0-5m).

5.Control room adopts heat-resistant materials and Midea/Gree air conditioner.

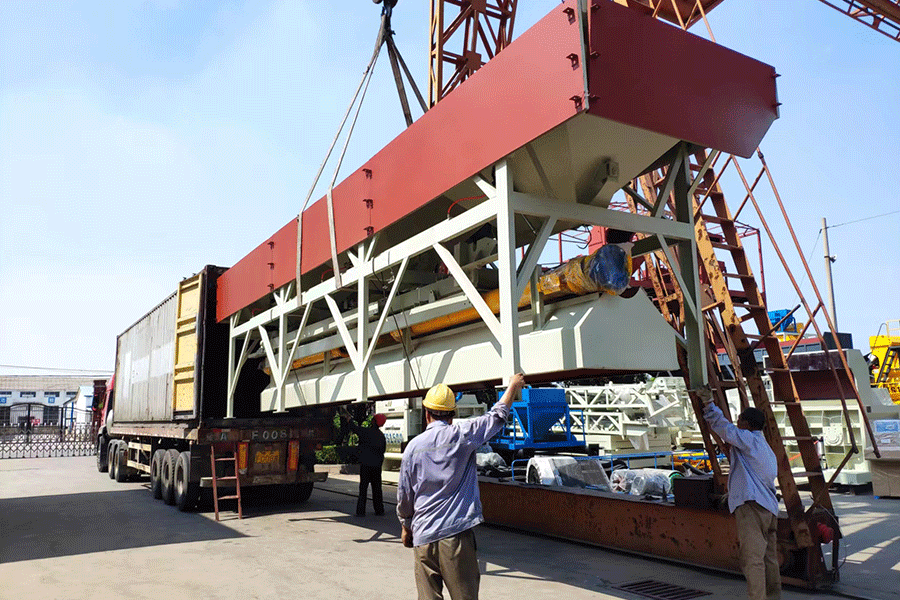

6.Quick installation and easy maintenance.

7.18-month warranty

8.Overall design can be customized (mixer, batching machine, silo, color, etc.)

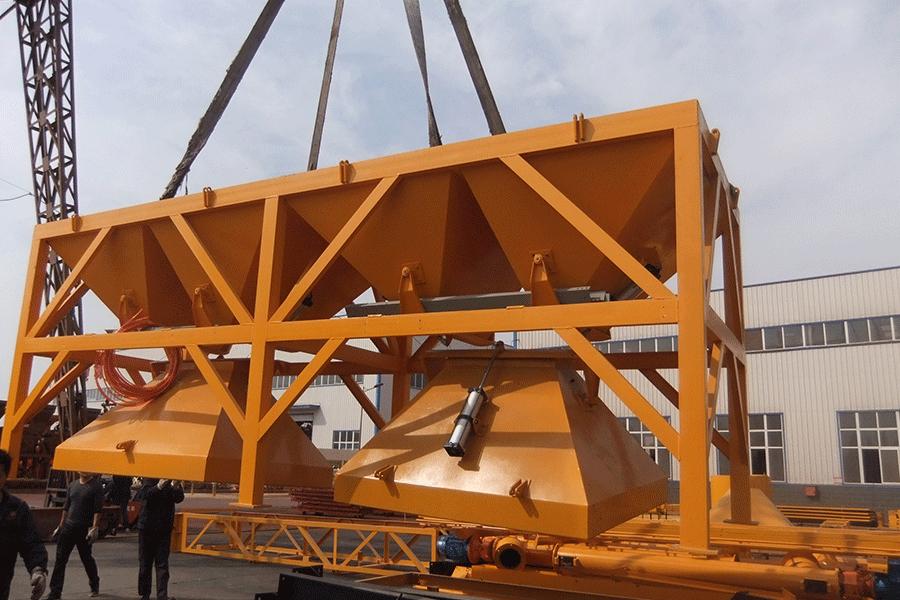

Delivery of conveyor belt concrete batching plant

More details on the conveyor belt-type concrete batching plant

Belt loading uses a conveyor belt for continuous and rapid loading. The design is more complex than the hopper lifting type loading, but the loading and transportation efficiency is high, which can quickly complete large-scale operation requirements and improve production efficiency by more than 20%;

The belt loading production cycle is short and the unloading volume is large, which is suitable for commercial concrete mixing stations;

It can continuously feed and has a large conveying distance, which can well meet the needs of large mixing stations;

The tensioning device ensures that the conveyor belt has sufficient tension and the friction between the conveyor belt and the transmission roller, so that the conveyor belt does not slip, and can adjust the impact of the change in the length of the conveyor belt;

The belt cover is mainly used for dust and rain protection.

The belt-type concrete mixing station has a series of characteristics such as high efficiency, stability, energy saving, and wide application. It is the best choice for commercial concrete mixing stations.

Parameters of conveyor belt type concrete batching plant

| Model | HZS60 | HZS90 | HZS120 | HZS180 | HZS240 | HZS270 |

| Capacity(m³/h) | 60 | 90 | 120 | 180 | 240 | 270 |

| Mixing system | Twin-shaft concrete mixer | |||||

| Aggregate feeder | Incline belt conveyor | |||||

| Discharging height(mm) | 4200 | |||||

| After-sale service | Erection & commissioning, operator training | |||||

| Warranty | 18 months | |||||

| Concrete mixer | JS1000 | JS1500 | JS2000 | JS3000 | JS4000 | JS4500 |

| Mixing cycle | ≤60s | |||||

| Aggregate batching machine(m³) | 4 x 8 | 4 x 12 | 4 x 20 | 4 x 25 | 4 x 25 | 4 x 25 |

| Weighing system | Water, Cement, Fly-Ash, Additive | |||||

| Weighing precision | ±1% | |||||

| Air system | Air compressor, etc | |||||

| Control system Type | Computer auto-control module ( PLC can be optional item) | |||||

| Control panel board | Buttons, lamps, indicators, CCTV, etc | |||||

| Electric components | China CHINT, SCHNEIDER | |||||

| Control room | With Air conditioner and chair | |||||

| Documentation | Foundation layout, Electrical diagram, Operation manual | |||||

| Optional Items | ||||||

| Screw conveyor diameter & length(mm) | Ø219/273, L=8000/9000 | |||||

| Cement silo capacity(t) | 50/100/150/200/300/500 | |||||

| Outer plant pack except aggregate bins | With main frame duct collector | |||||

Other concrete production equipment

Motor powered driven concrete pump price

Henan Hengyuan has been established for 25 years. As a professional concrete batching plant manufacturer, we have a professional technical team and production team, and can provide you with high-quality concrete batching plant equipment. All equipment is produced by our factory, and the price is the factory price.

For the specific price of the concrete batching plant, you can leave your contact information and production requirements. We will design the most suitable solution for you according to your actual site and production requirements, and provide the most favorable price.