A dry mix concrete batching plant is a simple concrete batching plant that mixes aggregates such as sand, crushed stone and cement according to precise measurement. It is mainly done by pouring the mixed materials into a mixer truck, mixing them with a certain amount of water, mixing them in the truck, and then transporting them to the construction site. Since a dry mix concrete batching plant does not include a mixer, it can save a lot of budget compared to a wet mix concrete batching plant.

The structure of dry mix concrete batching plant

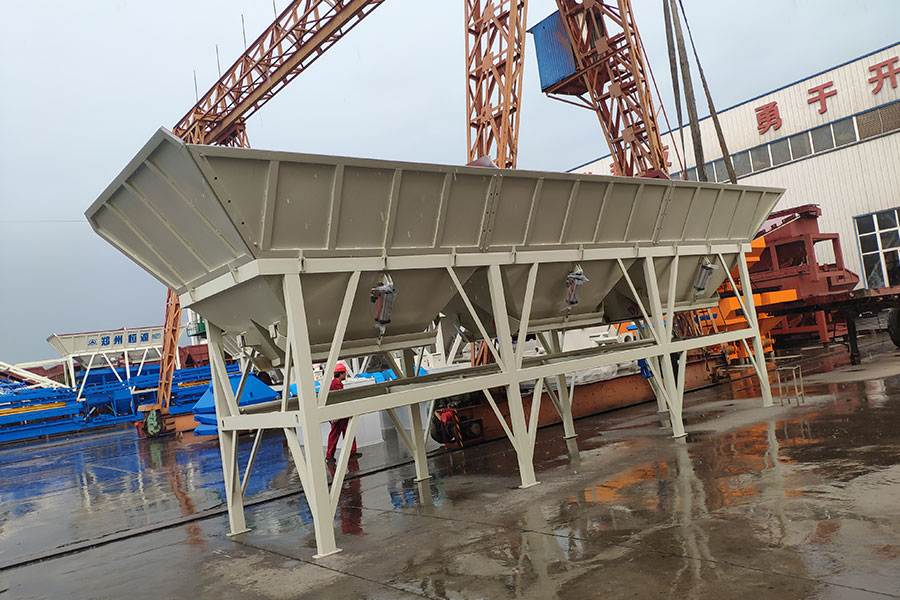

The dry mix concrete batching plant is mainly composed of batching machine, belt conveyor, weighing scale and cement silo. In the case that ready-mixed concrete needs to be transported to the construction site at a long distance, the dry process concrete batching plant is very convenient.

Working principle of dry mix concrete batching plant

Raw materials such as cement, sand, aggregates, etc. are put into the batching machine according to a certain ratio. After being accurately weighed and measured by the batching machine, the proportioned materials are transported to the transfer silo through the hopper. The mixed materials are then transported to the mixer truck through the transfer silo and mixed in the mixer truck.

Common types of dry mix concrete batching plant

HZS50D dry concrete batching plant

HZS50D dry mixing concrete batching plant is a dry process concrete batching plant with a processing capacity of up to 50m³/hour. It mainly uses belt conveyor for feeding and has a discharge height of 3.8 meters.

| Model | HZS50D |

| Capacity(m³/h) | 60 |

| Discharging height(mm) | 3800 |

| Batching machine model | PLD1600 |

HZS90D dry concrete batching plant

HZS90D dry mixing concrete batching plant is a dry process concrete batching plant with a processing capacity of up to 90m³/hour. It mainly uses belt conveyor for feeding and has a discharge height of 4 meters.

| Model | HZS90D |

| Capacity(m³/h) | 90 |

| Discharging height(mm) | 4000 |

| Batching machine model | PLD2400 |

HZS120D dry concrete batching plant

HZS120D dry mixing concrete batching plant is a dry process concrete batching plant with a processing capacity of up to 120m³/hour. It mainly uses belt conveyor for feeding and has a discharge height of 4 meters.

| Model | HZS120D |

| Capacity(m³/h) | 120 |

| Discharging height(mm) | 4000 |

| Batching machine model | PLD2400 |

HZS160D dry concrete batching plant

HZS160D dry mixing concrete batching plant is a dry process concrete batching plant with a processing capacity of up to 160m³/hour. It mainly uses belt conveyor for feeding and has a discharge height of 4.2 meters.

| Model | HZS160D |

| Capacity(m³/h) | 180 |

| Discharging height(mm) | 4200 |

| Batching machine model | PLD3200 |

HZS200D dry concrete batching plant

HZS200D dry mixing concrete batching plant is a dry process concrete batching plant with a processing capacity of up to 200m³/hour. It mainly uses belt conveyor for feeding and has a discharge height of 4.2 meters.

| Model | HZS200D |

| Capacity(m³/h) | 200 |

| Discharging height(mm) | 4200 |

| Batching machine model | PLD4800 |

Advantages of dry mix concrete batching plant

1.Easy installation and debugging.

2.Batching machine can be 2/3/4 storage silos with different capacities.

3.Conveyor belt can be customized with different capacities (width and height).

4.Fully automatic system is the same as wet mix concrete batching plant.

5.Cement feed can be cement hopper or cement silo.

Delivery of dry mix concrete batching plant

More details on the dry mix concrete batching plant

Higher production capacity. For traditional concrete batching plants, the mixing cycle takes 60 seconds, of which 25 to 30 seconds are used for mixing. For dry mix concrete batching plants, we do not have a mixer, so we can save half the time to get a batch. Output: 50-200 cubic meters/hour.

Reduce construction time and increase productivity.

Compared with wet mix equipment, dry mix concrete batching plants have lower power consumption.

Save costs. Since there is no concrete mixer, the output is higher and the energy consumption is lower.

Dry mix concrete plants are fully automatic like other mixing plants such as mobile and fixed ones.

Dry mix concrete batching plants are currently popular modern production equipment, and continue to play an important role in the construction and development of modern roads, bridges and various construction projects.

Parameters of dry mix concrete batching plant

| Model | HZS50D | HZS90D | HZS120D | HZS160D | HZS200D |

| Theoretical productivity(m³/h) | 60 | 90 | 120 | 180 | 200 |

| Batching machine model | PLD1600 | PLD2400 | PLD2400 | PLD3200 | PLD4800 |

| Feedig mode | Belt Conveyor | ||||

| Aggregate Batching accuracy | ≤±2% | ≤±2% | ≤±2% | ≤±2% | ≤±2% |

| Water Batching accuracy | ≤±1% | ≤±1% | ≤±1% | ≤±1% | ≤±1% |

| Cement Batching accuracy | ≤±1% | ≤±1% | ≤±1% | ≤±1% | ≤±1% |

| Additive Batching accuracy | ≤±1% | ≤±1% | ≤±1% | ≤±1% | ≤±1% |

| Discharging height(mm) | 3800 | 4000 | 4000 | 4200 | 4200 |

Other concrete production equipment

Dry mix concrete batching plant price

Henan Hengyuan has been established for 25 years. As a professional concrete batching plant manufacturer, we have a professional technical team and production team, and can provide you with high-quality dry concrete batching plant equipment. All equipment is produced by our factory, and the price is the factory price.

For the specific price of the concrete batching plant, you can leave your contact information and production requirements. We will design the most suitable solution for you according to your actual site and production requirements, and provide the most favorable price.