Henan Hengyuan-Manufacturer of various professional construction machinery and equipment

- Conveyor belt type concrete batching plant

- Skip hoist type concrete batching plant

- Dry mix concrete batching plant

- With-foundation concrete batching plant

- Container type concrete batching plant

- YHZM mobile concrete batching plant

- YHZS1.3 mobile concrete batching plant

- YHZS3.8 mobile concrete batching plant

Concrete Mixing Pump

What is a concrete mixing pump used for?

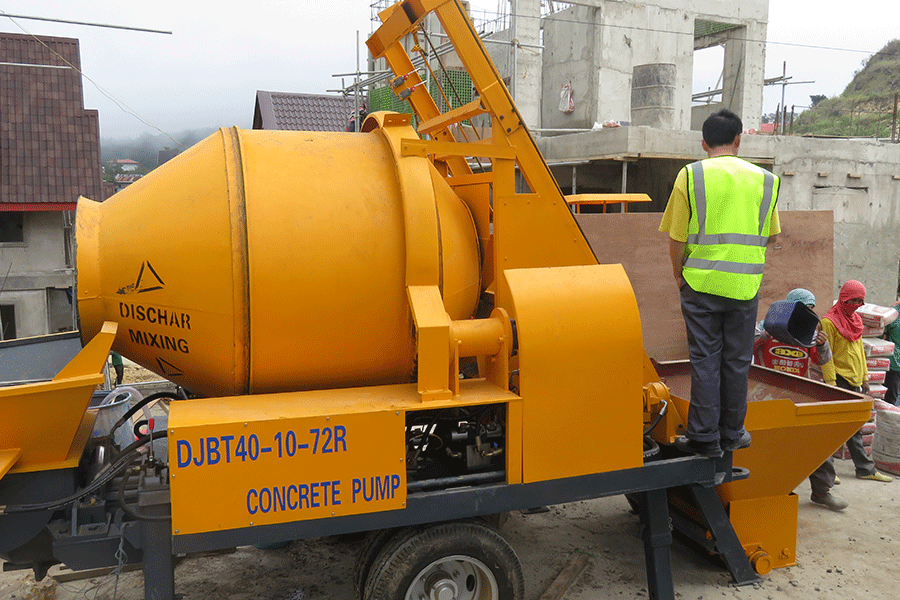

A concrete mixer pump is a concrete pump specifically designed for small civil buildings. It integrates feeding, mixing, and high-pressure pumping. This type of equipment has a high degree of automation, which can save a lot of labor costs. It is also simple to operate, has stable performance, and is easy to move. In large-scale building, bridge, and tunnel construction, concrete delivery pumps are commonly used equipment, and mixing and dragging pumps are one of them, suitable for construction scenarios that require efficient and stable concrete supply.

Concrete mixer pumps are designed to improve construction efficiency and quality, reduce manpower requirements through automated operation, and ensure uniform concrete mixing and continuous pumping. This type of equipment is highly safe during construction, has a very low failure rate, and has higher overall reliability than older equipment, thereby improving construction safety and efficiency.

In general, concrete mixer pumps are mainly used for concrete mixing and transportation, and are particularly suitable for construction projects that require automation and high efficiency, such as small civil buildings, large building construction, bridge construction, and tunnel construction.

Advantages and characteristics of concrete mixing pump

The advantages of concrete mixing pumps are mainly reflected in improving construction efficiency, reducing manpower and material consumption, improving concrete quality, strong adaptability, and saving labor.

1. Improve construction efficiency: Concrete mixing pumps can quickly and accurately transport concrete, reducing the need for manpower handling, thereby greatly improving construction efficiency and effectively saving labor costs and expenses.

2.Reduce manpower and material consumption: Compared with traditional concrete handling methods, concrete mixing pumps can reduce manpower consumption and do not require manual concrete handling, thereby reducing labor costs. At the same time, it can also reduce the loss and waste of concrete during transportation, further reducing material consumption.

3.Improve concrete quality: Concrete mixing pumps can reduce the segregation and slump loss of concrete during transportation, ensure the uniformity and stability of concrete, and improve the quality of concrete.

4.Strong adaptability: Concrete mixing pumps are suitable for various complex construction sites, such as self-built houses in rural areas, field engineering construction, etc., which improves construction quality and work efficiency.

5.Save labor: In concrete projects at civil residential and formwork construction sites, the use of concrete mixing pumps requires less labor and the concrete construction arrangement is very simple.

Features of concrete mixing pump

Save pressure: During the operation, the mixer pump truck can use the boom for longitudinal and transverse pumping and pouring, with high mechanization and automation in construction and high compressive strength.

Reduce pipeline blockage: It has a reverse pump function to minimize pipeline blockage and ensure smooth construction. In summary, the concrete mixer pump plays an important role in modern construction with its advantages of high efficiency, precise measurement, strong versatility, strong adaptability and guaranteed construction quality.

What are the commonly used concrete mixing pump?

Customize your concrete batching plant

Five different types of concrete mixing pump complete sets for sale

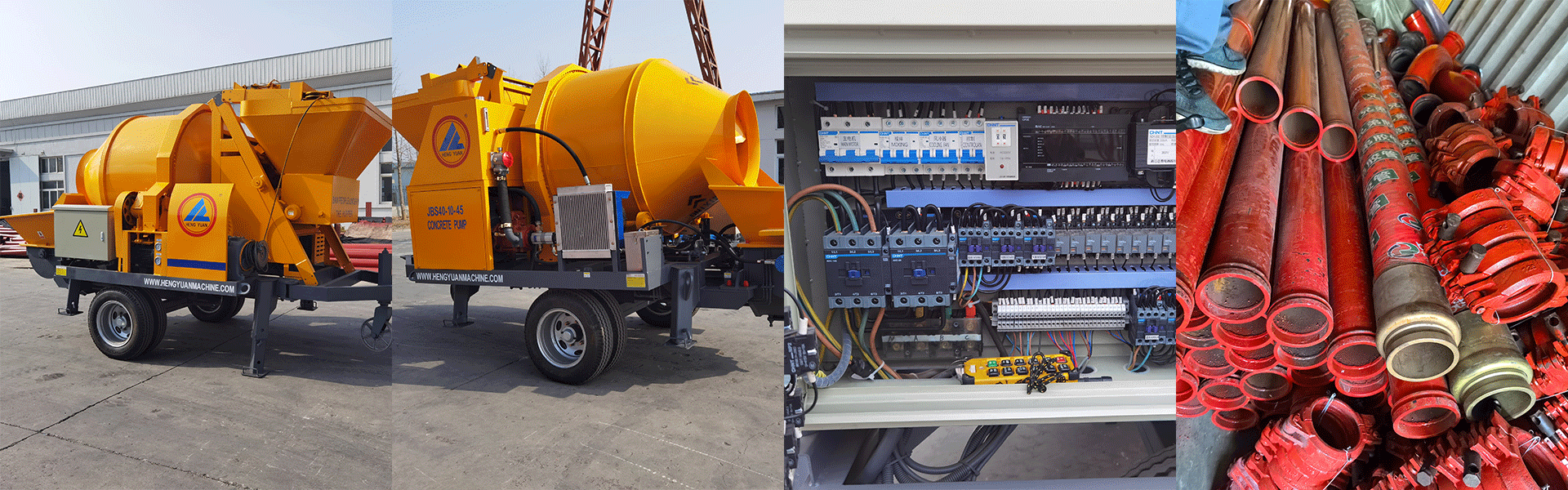

Concrete mixing pump is an integrated concrete mixing pumping equipment designed by our company based on the secondary research and development of concrete mixer and delivery pump. According to the different types of mixers, it can be divided into five different types of concrete mixing pumps. Motor-powered concrete mixing pump, diesel-powered concrete mixing pump, twin-shaft concrete mixing pump, disc concrete mixing pump, concrete mixing pump with batching machine. You can freely choose according to the actual site needs.

Motor powered concrete mixing pump

Diesel powered concrete mixing pump

Concrete pump with twin shaft mixer

Concrete pump with pan mixer

Concrete mixing pump with batching machine

Learn more about the concrete mixing pump?

What equipment does a concrete mixing pump?

Concrete mixer pump is a special equipment used for mixing and conveying concrete. It plays an important role in various engineering projects such as construction, roads, bridges, tunnels, etc. It is widely used in various engineering fields, such as building houses, roads, bridges and tunnels, canals, reservoirs, hydropower stations, and power tower piles, etc. It is one of the important equipment in the modern construction industry. The emergence of concrete mixer pump trucks has not only greatly optimized the work process and construction efficiency in rural areas, mountainous areas, and the wild, but also accelerated the development of the construction industry.

Other concrete production related equipment

Stationary concrete batching plant is a kind of concrete production equipment with high degree of mechanization and automation, which is widely used in large and medium-sized construction projects, roads, bridge projects and concrete prefabrication plants.

Stationary Concrete Batching Plant

| Model | Capacity(m³/h) | Concrete mixer | Aggregate batching machine(m³) |

| HZS60 | 60 | JS1000 | 4*8 |

| HZS90 | 90 | JS1500 | 4*12 |

| HZS120 | 120 | JS2000 | 4*20 |

| HZS180 | 180 | JS3000 | 4*25 |

| HZS240 | 240 | JS4000 | 4*25 |

| HZS270 | 270 | JS4500 | 4*25 |

The entire set of mobile concrete batching plant equipment adopts an integrated frame, equipped with a JS series twin-shaft mixer, and can work with a concrete pump, making it suitable for mobile operations in various sites.

Mobile Concrete Batching Plant

| Model | Capacity(m³/h) | Type of concrete mixer | Type of batching machine |

| YHZS25 | 25 | JS500 | PLD800 |

| YHZS35 | 35 | JS750 | PLD1200 |

| YHZS50 | 50 | JS1000 | PLD1600 |

| YHZS75 | 75 | JS1500 | PLD2400 |

| YHZS100 | 100 | JS2000 | PLD2400 |

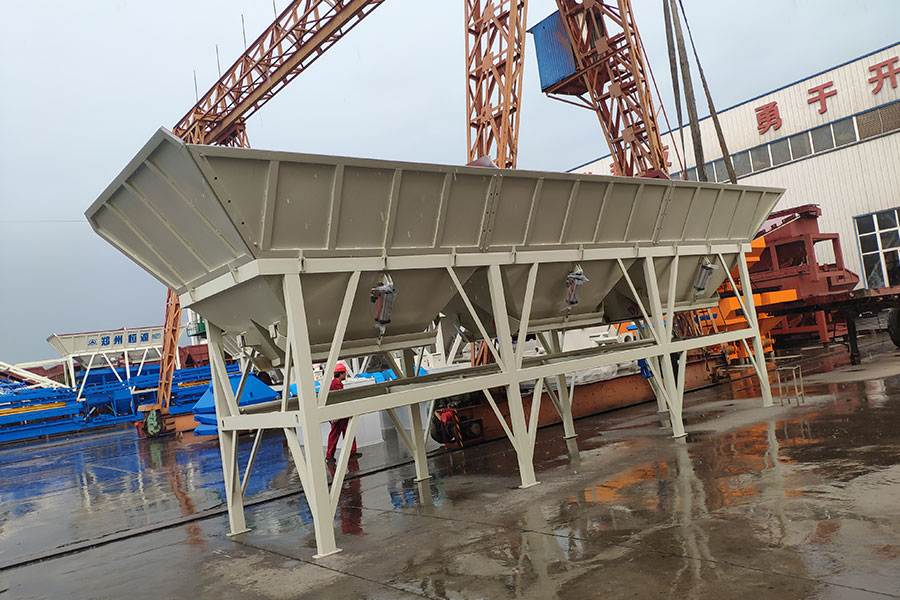

Concrete batching machine, also known as automatic sand and gravel batching machine, is an automated equipment used for quantitative distribution of various materials such as sand and gravel. It is mainly used in the concrete construction industry to replace manual weighing or volume measurement.

Batching Machine

| Model | Weighing hopper capacity (L) | Productivity (m³/h) | Feeding height (mm) |

| PLD800 | 800 | 48 | 2450 |

| PLD1200 | 1200 | 56 | 2950 |

| PLD1600 | 1600 | 75 | 2950 |

| PLD2400 | 2400 | 150 | 3700 |

| PLD3200 | 3200 | 200 | 4000 |

| PLD4800 | 4800 | 300 | 5000 |

Concrete mixer is a machine that mixes cement, sand and gravel aggregate and water to make concrete mixture. It has the dual advantages of independent operation of a single machine and forming a simple concrete mixing station with PLD series batching machine. It can provide a matching host for the mixing station and is suitable for various large, medium and small prefabricated component factories and industrial and civil construction projects such as highways, bridges, water conservancy, docks, etc.

Twin shaft concrete mixer

| Model | Discharge capacity (L) | Feed capacity (L) | Machine weight (kg) |

| JS500 | 500 | 800 | 4000 |

| JS750 | 750 | 1200 | 5500 |

| JS1000 | 1000 | 1600 | 8700 |

| JS1500 | 1500 | 2400 | 11130 |

| JS2000 | 2000 | 3200 | 15000 |

| JS3000 | 3000 | 4200 | 20000 |

The drum mixer is also called a self-falling double-cone reverse discharging concrete mixer. It mixes in the forward direction and discharges in the reverse direction. It can mix plastic and semi-dry hard concrete. The mixing drum of this machine is driven by a gear ring or a rubber roller friction drive. It has the advantages of reliable transmission, light weight, low energy consumption, compact structure, stable operation, simple operation, good mixing quality, and high production efficiency. It is suitable for general construction sites, roads, bridges, hydropower and other projects and small and medium-sized concrete component plants.

Drum mixer

| Model | Discharge capacity (L) | Feed capacity (L) | Machine weight (kg) |

| JZC250 | 250 | 320 | 1300 |

| JZC350 | 350 | 560 | 1950 |

| JZM350 | 350 | 560 | 1970 |

| JZC500 | 500 | 800 | 3100 |

| JZM500 | 500 | 800 | 4100 |

| JZC750 | 750 | 1200 | 4200 |

| JZM750 | 750 | 1200 | 5500 |

Screw conveyor is a machine that uses a motor to drive the screw to rotate and push materials to achieve the purpose of conveying. It is a mechanical transportation equipment that uses the special structure of the spiral blade and the gap between the spiral blade and the fixed spiral groove to continuously convey materials.

Screw Conveyor

| Model | Spiral diameter (mm) | Shell diameter (mm) | Motor power (kw) |

| LSY160 | 160 | 194 | 3-7.5 |

| LSY200 | 193 | 219 | 4-11 |

| LSY250 | 250 | 273 | 7.5-15 |

| LSY300 | 300 | 325 | 11-22 |

Cement silos are generally used for bulk cement storage in concrete mixing plants. They are suitable for storing various bulk building materials such as cement and fly ash. The silo is equipped with a material level system that can display the location and amount of the material.

Cement silo

| Model | Tank diameter (m) | Tank height (m) | Total tank height (m) |

| SNC30T | 2.5 | 4.8 | 11.4 |

| SNC50T | 3 | 5.4 | 12 |

| SNC80T | 3 | 9 | 15.6 |

| SNC100T | 3 | 11.4 | 18 |

| SNC150T | 3 | 23.5 | 29 |

| SNC200T | 4.5 | 18.6 | 25.2 |

| SNC300T | 4.5 | 24.6 | 29.5 |

| SNC500T | 6 | 22.2 | 28.8 |

What can we do for you?

As a professional construction machinery manufacturer, Henan Hengyuan Co., Ltd. not only has a professional technical team, but also has excellent machine quality. At present, the global construction industry is still developing. The concrete mixing plants produced by Henan Hengyuan are often used in large and medium-sized water conservancy, power, bridge and other projects with large concrete engineering volume, long construction period and concentrated construction sites. With the development of municipal construction, the mixing plants that use centralized mixing and provide commercial concrete have great advantages, so they have been rapidly developed, creating conditions for promoting concrete pumping construction and realizing the linkage operation of mixing, conveying and pouring machinery.

1.We will initially select the corresponding machine for you according to your production needs.

2.We will calculate your corresponding site and factory area according to your production requirements and give you factory construction suggestions.

3.After we determine the factory or production line area with you, our professional technical engineers will draw professional installation plans and machine layout drawings for you.

4.If you encounter any problems during the installation of the production line, you can communicate with us at any time. We will send professional installation engineers for video guidance or on-site installation guidance.

5.If you encounter any problems during the production process, just make a phone call and we will help you solve them at any time.