Henan Hengyuan-Manufacturer of various professional construction machinery and equipment

- Conveyor belt type concrete batching plant

- Skip hoist type concrete batching plant

- Dry mix concrete batching plant

- With-foundation concrete batching plant

- Container type concrete batching plant

- YHZM mobile concrete batching plant

- YHZS1.3 mobile concrete batching plant

- YHZS3.8 mobile concrete batching plant

Mobile Concrete Batching Plant

What is a mobile concrete batching plant used for?

What is a mobile concrete batching plant used for? We must first know what concrete is? Concrete is a building material made by mixing cement, sand, stone and other aggregates and water in a certain proportion with a mixer. It is generally composed of aggregates (sand, stone); powder (cement, fly ash, mineral powder, powdered admixture); water; liquid admixture.

The mechanical equipment for producing concrete is called a concrete batching station. First, the raw materials are mixed in a certain proportion by a batching machine and then transported to a concrete mixer for mixing to form a homogeneous concrete mixture. After mixing, the concrete mixture will enter the concrete transport vehicle through the discharge port.

The mobile concrete batching station is a complete set of fully automatic concrete mixing equipment consisting of batching, mixing, electrical control and other parts. It is mainly suitable for medium-sized and above construction sites, highways, bridges, prefabricated parts plants and commercial concrete production plants.

Advantages and characteristics of mobile concrete batching plant

The advantages of mobile concrete mixing plants mainly include high flexibility, efficient production, convenient maintenance, strong adaptability and strong mobility.

1.High flexibility: Mobile concrete mixing plants can be moved to different construction sites at any time, without repeated investment, reducing costs. This flexibility makes it very suitable for engineering projects that require frequent changes in work locations.

2.Efficient production: Mobile concrete mixing plants can quickly produce a large amount of concrete in a short period of time to meet the needs of construction sites. This efficient production capacity is particularly important for rushing deadlines or emergency projects.

3.Easy maintenance: The various components of mobile concrete mixing plants are relatively independent, easy to replace, and relatively simple to maintain. This reduces maintenance costs and time and improves the availability of equipment.

4.Strong adaptability: It adopts a component design that can be quickly installed and disassembled, and can be assembled according to construction needs to adapt to various terrains and sites. This adaptability enables mobile concrete mixing plants to perform well in various construction environments.

5.Strong mobility: The wheels and axles of the mobile concrete mixing plant can be moved, which is convenient for transportation and can be quickly transferred from one construction site to another. This mobility greatly improves the efficiency of resource utilization.

Features of mobile concrete batching plant

In addition, the mobile concrete mixing plant also has the following characteristics:

7.Easy to move: Usually tires are installed at the bottom, and the work site can be transferred by truck, and the modular design is also convenient for disassembly and transportation.

8.Occupy less space: The structure is often more compact, and the model is often not very large, so it does not require a lot of space or high cost.

9.Not demanding on ground hardening: The machine itself has a small weight, and the pressure on the surface is not large, so it can be used directly on ordinary concrete floors

What are the commonly used mobile concrete batching plant?

Customize your concrete batching plant plant

Three different types of mobile concrete batching plant complete sets for sale

Mobile concrete batching plant is the most common equipment in concrete production. It can be divided into drum mobile type and twin-shaft mobile type according to the type of mixer. Twin-shaft mobile concrete batching station can be divided into YHZS1.3 mobile concrete batching station with a discharge height of 1.3 meters and YHZS3.8 mobile concrete batching station with a discharge height of 3.8 meters according to the different discharge heights. You can choose the most suitable concrete mixing station according to actual production needs and site requirements.

YHZM mobile concrete batching plant

YHZS1.3 mobile concrete batching plant

YHZS3.8 mobile concrete batching plant

Learn more about the concrete batching plant?

What equipment does a mobile concrete batching plant?

Concrete batching plant is a kind of equipment for producing concrete. It is generally divided into fixed type and mobile type. Common equipment includes: batching machine, concrete mixer, screw conveyor, cement silo and other equipment.

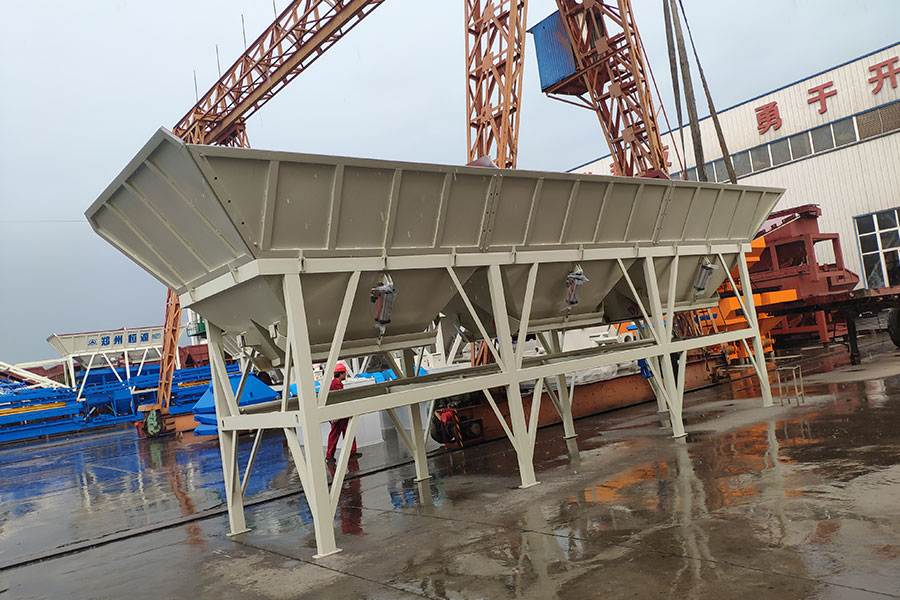

Concrete batching machine, also known as automatic sand and gravel batching machine, is an automated equipment used for quantitative distribution of various materials such as sand and gravel. It is mainly used in the concrete construction industry to replace manual weighing or volume measurement.

Batching Machine

| Model | Weighing hopper capacity (L) | Productivity (m³/h) | Feeding height (mm) |

| PLD800 | 800 | 48 | 2450 |

| PLD1200 | 1200 | 56 | 2950 |

| PLD1600 | 1600 | 75 | 2950 |

| PLD2400 | 2400 | 150 | 3700 |

| PLD3200 | 3200 | 200 | 4000 |

| PLD4800 | 4800 | 300 | 5000 |

Concrete mixer is a machine that mixes cement, sand and gravel aggregate and water to make concrete mixture. It has the dual advantages of independent operation of a single machine and forming a simple concrete mixing station with PLD series batching machine. It can provide a matching host for the mixing station and is suitable for various large, medium and small prefabricated component factories and industrial and civil construction projects such as highways, bridges, water conservancy, docks, etc.

Twin shaft concrete mixer

| Model | Discharge capacity (L) | Feed capacity (L) | Machine weight (kg) |

| JS500 | 500 | 800 | 4000 |

| JS750 | 750 | 1200 | 5500 |

| JS1000 | 1000 | 1600 | 8700 |

| JS1500 | 1500 | 2400 | 11130 |

| JS2000 | 2000 | 3200 | 15000 |

| JS3000 | 3000 | 4200 | 20000 |

The drum mixer is also called a self-falling double-cone reverse discharging concrete mixer. It mixes in the forward direction and discharges in the reverse direction. It can mix plastic and semi-dry hard concrete. The mixing drum of this machine is driven by a gear ring or a rubber roller friction drive. It has the advantages of reliable transmission, light weight, low energy consumption, compact structure, stable operation, simple operation, good mixing quality, and high production efficiency. It is suitable for general construction sites, roads, bridges, hydropower and other projects and small and medium-sized concrete component plants.

Drum mixer

| Model | Discharge capacity (L) | Feed capacity (L) | Machine weight (kg) |

| JZC250 | 250 | 320 | 1300 |

| JZC350 | 350 | 560 | 1950 |

| JZM350 | 350 | 560 | 1970 |

| JZC500 | 500 | 800 | 3100 |

| JZM500 | 500 | 800 | 4100 |

| JZC750 | 750 | 1200 | 4200 |

| JZM750 | 750 | 1200 | 5500 |

Screw conveyor is a machine that uses a motor to drive the screw to rotate and push materials to achieve the purpose of conveying. It is a mechanical transportation equipment that uses the special structure of the spiral blade and the gap between the spiral blade and the fixed spiral groove to continuously convey materials.

Screw Conveyor

| Model | Spiral diameter (mm) | Shell diameter (mm) | Motor power (kw) |

| LSY160 | 160 | 194 | 3-7.5 |

| LSY200 | 193 | 219 | 4-11 |

| LSY250 | 250 | 273 | 7.5-15 |

| LSY300 | 300 | 325 | 11-22 |

Cement silos are generally used for bulk cement storage in concrete mixing plants. They are suitable for storing various bulk building materials such as cement and fly ash. The silo is equipped with a material level system that can display the location and amount of the material.

Cement silo

| Model | Tank diameter (m) | Tank height (m) | Total tank height (m) |

| SNC30T | 2.5 | 4.8 | 11.4 |

| SNC50T | 3 | 5.4 | 12 |

| SNC80T | 3 | 9 | 15.6 |

| SNC100T | 3 | 11.4 | 18 |

| SNC150T | 3 | 23.5 | 29 |

| SNC200T | 4.5 | 18.6 | 25.2 |

| SNC300T | 4.5 | 24.6 | 29.5 |

| SNC500T | 6 | 22.2 | 28.8 |

What can we do for you?

As a professional construction machinery manufacturer, Henan Hengyuan Co., Ltd. not only has a professional technical team, but also has excellent machine quality. At present, the global construction industry is still developing. The concrete mixing plants produced by Henan Hengyuan are often used in large and medium-sized water conservancy, power, bridge and other projects with large concrete engineering volume, long construction period and concentrated construction sites. With the development of municipal construction, the mixing plants that use centralized mixing and provide commercial concrete have great advantages, so they have been rapidly developed, creating conditions for promoting concrete pumping construction and realizing the linkage operation of mixing, conveying and pouring machinery.

1.We will initially select the corresponding machine for you according to your production needs.

2.We will calculate your corresponding site and factory area according to your production requirements and give you factory construction suggestions.

3.After we determine the factory or production line area with you, our professional technical engineers will draw professional installation plans and machine layout drawings for you.

4.If you encounter any problems during the installation of the production line, you can communicate with us at any time. We will send professional installation engineers for video guidance or on-site installation guidance.

5.If you encounter any problems during the production process, just make a phone call and we will help you solve them at any time.