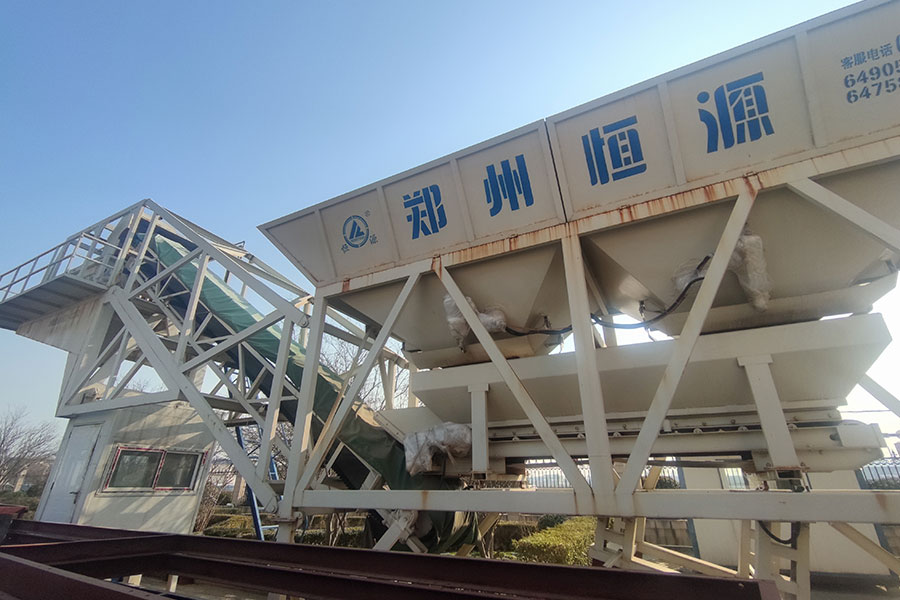

YHZS3.8 mobile concrete batching plant is a new type of mobile concrete batching station developed by Henan Hengyuan on the basis of mobile concrete batching station. The whole set of equipment adopts an integrated frame, matched with JS series twin-shaft mixer, with a discharge height of 3.8 meters, which is suitable for mobile operations in various sites.

The structure of YHZS3.8 mobile concrete batching plant

YHZS3.8 mobile concrete batching station is mainly composed of aggregate/fly ash/cement/additive/water batching system, mixing system, conveying system, automatic control system, mobile frame, etc.

Working principle of YHZS3.8 mobile concrete batching plant

Raw materials such as cement, sand, aggregates, etc. are put into the batching machine according to a certain ratio. After being accurately weighed and measured by the batching machine, the proportioned materials are transported to the JS series concrete mixer via a conveyor. After being evenly mixed by the concrete mixer, they fall from a height of 3.8 meters into the belt conveyor or mixing pump for coordinated operation.

Common types of YHZS3.8 mobile concrete batching plant

YHZS25 mobile concrete batching plant

YHZS25 mobile concrete batching plant is a mobile concrete batching plant with a processing capacity of up to 25m³ per hour. It mainly adopts JS500 twin-shaft mixer and has a discharge height of 3.8m to meet various production scenarios.

| Model | YHZS25 |

| Capacity(m³/h) | 25 |

| Concrete mixer | JS500 |

| Batching machine model | PLD800 |

YHZS35 mobile concrete batching plant

YHZS35 mobile concrete batching plant is a mobile concrete batching plant with a processing capacity of up to 35m³ per hour. It mainly adopts JS750 twin-shaft mixer and has a discharge height of 3.8m to meet various production scenarios.

| Model | YHZS35 |

| Capacity(m³/h) | 35 |

| Concrete mixer | JS750 |

| Batching machine model | PLD1200 |

YHZS50 mobile concrete batching plant

YHZS50 mobile concrete batching plant is a mobile concrete batching plant with a processing capacity of up to 50m³ per hour. It mainly adopts JS1000 twin-shaft mixer and has a discharge height of 3.8m to meet various production scenarios.

| Model | YHZS50 |

| Capacity(m³/h) | 50 |

| Concrete mixer | JS1000 |

| Batching machine model | PLD1600 |

YHZS75 mobile concrete batching plant

YHZS75 mobile concrete batching plant is a mobile concrete batching plant with a processing capacity of up to 75m³ per hour. It mainly adopts JS1500 twin-shaft mixer and has a discharge height of 3.8m to meet various production scenarios.

| Model | YHZS75 |

| Capacity(m³/h) | 75 |

| Concrete mixer | JS1500 |

| Batching machine model | PLD2400 |

YHZS100 mobile concrete batching plant

YHZS100 mobile concrete batching plant is a mobile concrete batching plant with a processing capacity of up to 100m³ per hour. It mainly adopts JS2000 twin-shaft mixer and has a discharge height of 3.8m to meet various production scenarios.

| Model | YHZS100 |

| Capacity(m³/h) | 100 |

| Concrete mixer | JS2000 |

| Batching machine model | PLD2400 |

Advantages of YHZS3.8 mobile concrete batching plant

1.Fully automatic control system, PLC adopts Siemens brand, and main electrical components adopt Schneider/CHNT brand.

2.Control panel and system language can be customized.

3.Mixing system uses JS/SICOMA twin-shaft concrete mixer or planetary mixer, which has high mixing efficiency and high mixing quality.

4.Convenient transportation, no other installation is required except the first installation.

5.The control room is foldable and uses heat-resistant materials and Midea/Gree air conditioners.

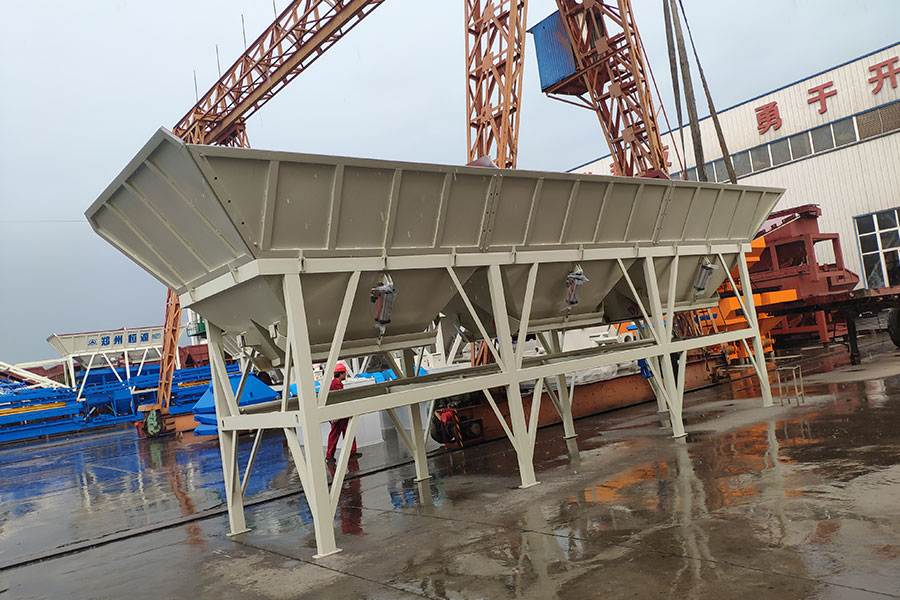

6.Batching machine is equipped with 2 or 4 aggregate storage silos.

7.Cement silos are specially designed for transportation (4 sets/40HQ)

8.18-month warranty.

9.The overall design can be customized (mixer, batching machine, silo, color, etc.)

Delivery of YHZS3.8 mobile concrete batching plant

More details on the YHZS3.8 mobile concrete batching plant

Quick assembly and disassembly, convenient transportation. Except for external equipment such as screw conveyors and cement silos, all cable connections do not need to be removed.

Excellent mixing performance. The twin-shaft concrete mixer is used to mix the concrete evenly in the shortest time. Different mix ratios such as dry hard concrete, semi-dry hard concrete, and plastic concrete can be mixed evenly.

First-class configuration, high reliability, accurate measurement, and easy operation. The main electrical components of the concrete mixer reducer, weighing sensor, control system, etc. are all imported brands, which reduces the failure rate and improves the weighing accuracy of the equipment.

Parameters of YHZS3.8 mobile concrete batching plant

| Model | YHZS25 | YHZS35 | YHZS50 | YHZS75 | YHZS100 |

| Capacity(m³/h) | 25 | 35 | 50 | 75 | 100 |

| Mixing system | Twin-shaft concrete mixer | ||||

| Discharging height(mm) | 3800 | ||||

| Max. Dragging Speed(km/h) | 40 | ||||

| After-sale service | Erection & commissioning, operator training | ||||

| Warranty | 18months | ||||

| Concrete mixer model | JS500 | JS750 | JS1000 | JS1500 | JS2000 |

| Aggregate batching machine | PLD800 | PLD1200 | PLD1600 | PLD2400 | PLD2400 |

| Aggregate feediing way | Belt conveyor | ||||

| Weighing system | Water, Cement, Fly-Ash, Additive | ||||

| Weighing precision | ±1% | ||||

| Air system | Air compressor, etc | ||||

| Dragging chassis | Drag rod & Leading steering, Front/Back axle & shock absorption, back wheel, Outrigger | ||||

| Optional Items | |||||

| Screw conveyor diameter & length(mm) | Ø219/273, L=8000/9000 | ||||

| Cement silo capacity(t) | 50/100/150/200 | ||||

Other concrete production equipment

YHZS3.8 mobile concrete batching plant price

Henan Hengyuan has been established for 25 years. As a professional concrete batching plant manufacturer, we have a professional technical team and production team, and can provide you with high-quality mobile concrete batching plant equipment. All equipment is produced by our factory, and the price is the factory price.

For the specific price of the concrete batching plant, you can leave your contact information and production requirements. We will design the most suitable solution for you according to your actual site and production requirements, and provide the most favorable price.