Concrete Batching Plant

A concrete batching plant, also known as a concrete mixing plant, operates as a specialized facility for producing concrete. By accurately measuring and mixing ingredients such as aggregates, cement, water, and admixtures, the plant produces concrete that meets specific strength and durability requirements. This equipment therefore plays a crucial role in modern construction projects and is widely used by teams in applications including road and bridge construction, building projects, and water conservancy works.

Types of concrete batching plants

Concrete batching plants play an indispensable role in modern construction projects. Their efficient and precise production capabilities consistently ensure a reliable supply of concrete for various engineering needs. Therefore, selecting the appropriate type and configuration of a concrete mixing plant can significantly enhance on-site efficiency and, ultimately, ensure the quality of the project.

Stationary batching plant: suitable for long-term large-scale projects with high production capacity.

Mobile batching plant: It is highly portable and suitable for projects that require frequent relocation.

Dry mix batching plant: adds water during transportation, suitable for projects requiring intermittent concrete supply.

Wet mix batching plant: adds water to mix before loading, suitable for projects requiring high quality concrete.

Working principle of concrete batching plant

First, raw materials such as cement, sand, and aggregates are added to the batching machine in a certain proportion. Then, the batching machine accurately weighs and measures the materials. Next, the proportioned materials are transported to the concrete mixer via a belt conveyor. After being uniformly mixed in the mixer, the mixture is finally transported to a mixer truck or concrete pump via a belt conveyor or screw conveyor for use in on-site construction.

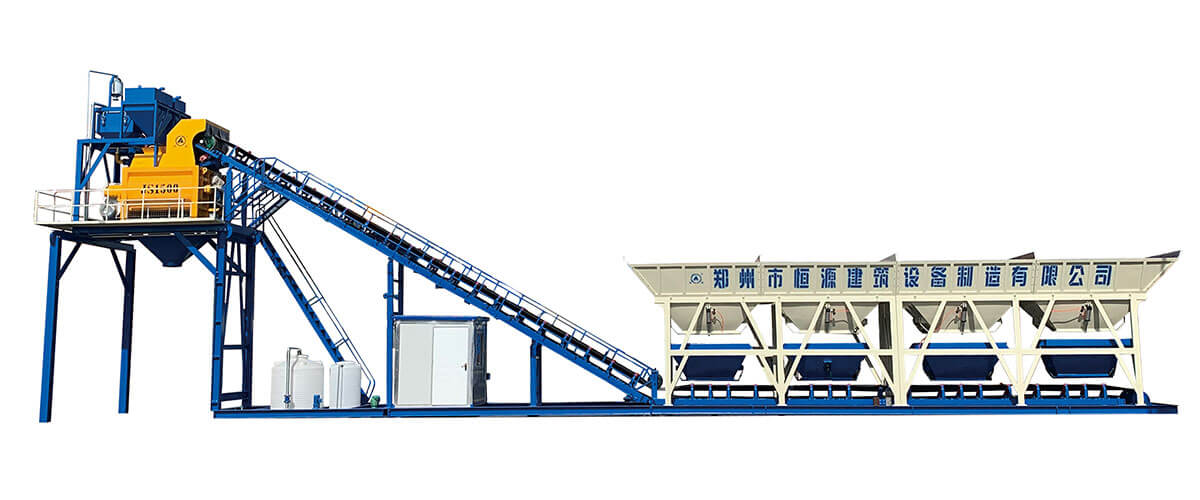

The composition of concrete batching plant

A concrete batching plant, also known as a concrete mixing plant, combines several key components that work together to produce concrete that meets specific requirements. The following components form the main structure of a concrete batching plant:

Mixing machine

As the core of the entire batching plant, it is responsible for mixing various raw materials into concrete. Among them, the forced mixer is more commonly used due to its high-efficiency mixing capacity and wide applicability.

Material weighing system

The system’s function is to accurately measure the weight of various raw materials to ensure the quality and strength of concrete. Furthermore, the weighing system can be divided into three parts: aggregate weighing, powder weighing, and liquid weighing.

Material conveying system

First, the conveying system transports raw materials—such as aggregates, powders, and liquids—from the storage area to the mixer. Specifically, it uses belt conveyors or hoppers to move aggregates, screw conveyors to deliver powders, and water pumps to convey liquid materials.

Material storage system

This system is used to store various raw materials. Typically, aggregates are stored in the open, while powders and water are stored in sealed containers to prevent contamination and spoilage.

Control system

As the core of the batching plant, the control system actively coordinates and manages the entire production process. It automatically operates each component according to preset process parameters, thereby ensuring consistent concrete quality and reliable production performance.

Other auxiliary facilities

In addition, it includes cement silos, admixture storage tanks, electrical systems, etc. These facilities provide support and necessary auxiliary functions for the normal operation of the mixing plant.

Parameters of concrete batching plants

The concrete batching station uses different main machines according to different capacities, and the specific parameters need to be determined according to the actual situation.

| Model | HZS60 | HZS90 | HZS120 | HZS180 | HZS240 | HZS270 |

| Capacity(m³/h) | 60 | 90 | 120 | 180 | 240 | 270 |

| Mixing system | Twin-shaft concrete mixer | |||||

| Aggregate feeder | Incline belt conveyor | |||||

| Discharging height(mm) | 4200 | |||||

| After-sale service | Erection & commissioning, operator training | |||||

| Warranty | 18 months | |||||

| Concrete mixer | JS1000 | JS1500 | JS2000 | JS3000 | JS4000 | JS4500 |

| Mixing cycle | ≤60s | |||||

| Aggregate batching machine(m³) | 4 x 8 | 4 x 12 | 4 x 20 | 4 x 25 | 4 x 25 | 4 x 25 |

| Weighing system | Water, Cement, Fly-Ash, Additive | |||||

| Weighing precision | ±1% | |||||

| Air system | Air compressor, etc | |||||

| Control system Type | Computer auto-control module ( PLC can be optional item) | |||||

| Control panel board | Buttons, lamps, indicators, CCTV, etc | |||||

| Electric components | China CHINT, SCHNEIDER | |||||

| Control room | With Air conditioner and chair | |||||

| Documentation | Foundation layout, Electrical diagram, Operation manual | |||||

| Optional Items | ||||||

| Screw conveyor diameter & length(mm) | Ø219/273, L=8000/9000 | |||||

| Cement silo capacity(t) | 50/100/150/200/300/500 | |||||

| Outer plant pack except aggregate bins | With main frame duct collector | |||||

Application areas of concrete batching plants

Concrete batching plants serve as indispensable equipment for the modern construction industry. As a result, contractors and project managers widely deploy them across a diverse range of projects, including general construction, bridge and tunnel engineering, public infrastructure, and road or highway work. Furthermore, these plants are essential for water conservancy projects, the production of prefabricated components, commercial and industrial building developments, specialized applications, and environmentally friendly construction methods.

Choosing the right supplier means choosing the future

Before starting your concrete batching plant project, you need to choose a suitable supplier to provide you with long-term support and service. Henan Hengyuan is undoubtedly one of your best choices.

Years of manufacturing experience, standardized manufacturing process, and excellent machine quality.

Professional technical team, constantly optimizing machine details to meet customer needs.

Years of foreign trade sales experience, familiar with the delivery process, fast and efficient.

Factory direct sales price, all machines are manufactured by independent factories.

Customizable solution details to meet your actual production customization needs.

Control system with exclusive operating language, convenient and fast daily operation.

Installation solution is provided, and installation design is carried out according to the actual site size.

Technical guidance, providing engineers with remote technical guidance or on-site guidance.

Henan Hengyuan’s machines are shipped all over the world

As a foreign trade factory with many years of experience in loading containers, our machines and equipment are shipped all over the world.

Ready to start your project?

Are you ready to start your own project, but don’t know how to proceed? You can contact us to leave your requirements and details, and we will provide you with a detailed engineering solution.

Study local market demand and peer sales data. Design and plan relevant project budgets and plans.

Determine the size and location of the project site and apply for relevant project licenses.

Select a suitable equipment supplier and install and test the equipment effect.

After testing, the project will be officially put into operation, and production data statistics will be prepared to facilitate the calculation of profits.

Carry out long-term maintenance and care of machinery and equipment, and replace wearing parts regularly.

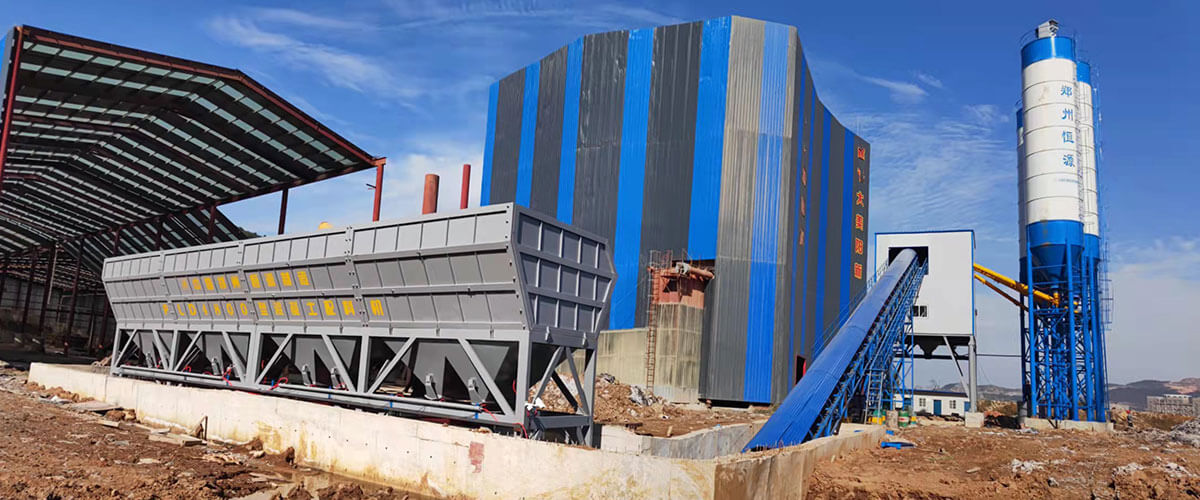

Our client case site

Henan Hengyuan is a professional concrete batching plant manufacturer, and its concrete batching plants are sold in more than 100 countries around the world.

More products

We not only produce various concrete batching plants, but also various types of concrete pumps, concrete mixing pumps, stabilized soil mixing plants and various concrete mixers.