Concrete Pumps

A trailer concrete pump is a mechanical device designed for concrete transportation and placement. As one of the earliest forms of concrete pumping equipment, it efficiently delivers concrete to high or long-distance locations on construction sites.

Due to its stable performance and wide adaptability, the construction industry widely applies trailer concrete pumps in urban development, bridge construction, power plants, and other energy infrastructure projects.

Types of Concrete Pumps

A concrete pump is a piece of mechanical equipment used in construction projects, primarily used to deliver liquid concrete (also known as ready-mixed concrete) from a self-loading concrete mixer, concrete mixer truck or concrete mixing plant to the desired location on a construction site.

Motor-powered concrete pump: suitable for various application scenarios and areas with stable power supply.

Diesel-powered concrete pump: suitable for areas with power shortage and easy and fast movement.

Working principle of Concrete Pump

After the batching plant produces the concrete, it first feeds the material directly into the hopper of the concrete trailer pump. Once the pump is started, the concrete then flows from the hopper into the inlet and is continuously pushed backward by the screw conveyor inside the volumetric hopper.

At the same time, the concrete delivery cylinder applies steady pressure, thereby forcing the concrete into the outlet pipe. As pressure builds up, a pressure difference rapidly forms, which in turn creates a stable and continuous pumping action.

Consequently, the system achieves efficient and reliable concrete transportation from the batching plant to the construction site.

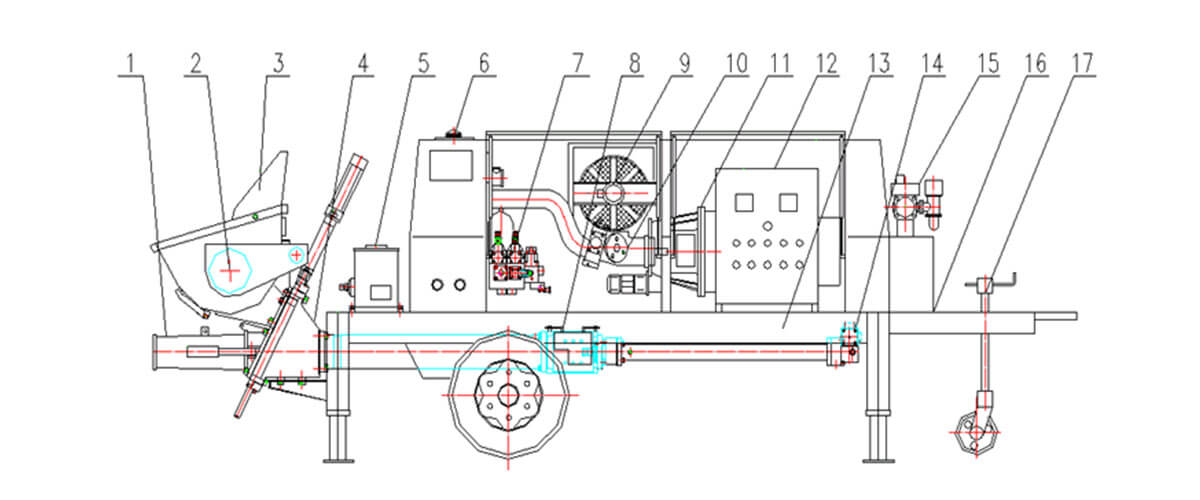

The composition of Concrete Pump

The concrete pump is mainly composed of a radiator, a motor/diesel engine, a control system, a hydraulic oil pump, a lubrication system, a sealing system, a mobile frame, concrete pipes and accessories.

Motor

The concrete pump is equipped with a motor from a globally recognized brand and supports optional Siemens motor configuration based on customer requirements. In addition, the motor voltage can be customized to match the customer’s local power supply, ensuring stable operation under different on-site conditions.

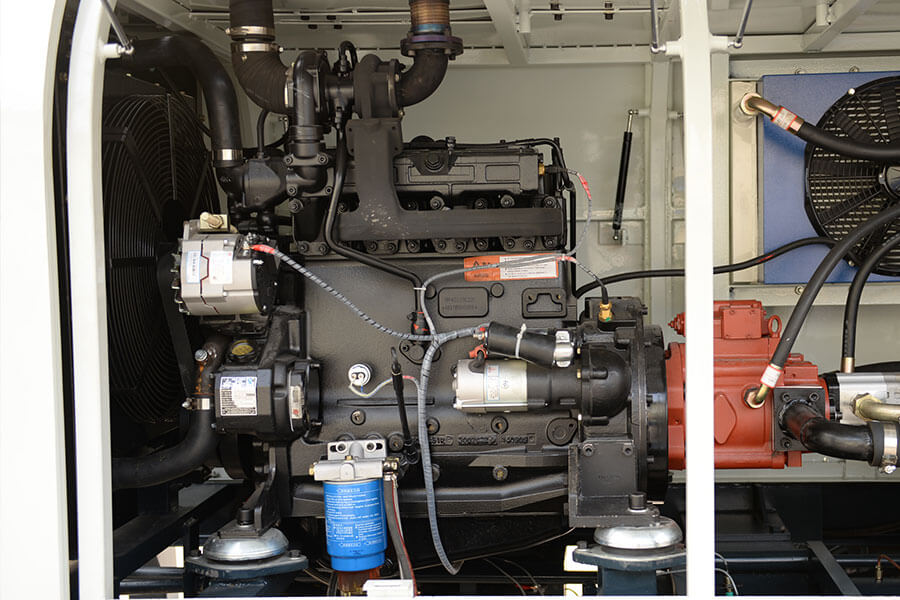

Diesel engine

The concrete pump uses a well-known domestic diesel engine and supports optional Cummins or other international brands according to customer requirements. During operation, the engine maintains stable oil pressure, ensuring reliable performance and long service life.

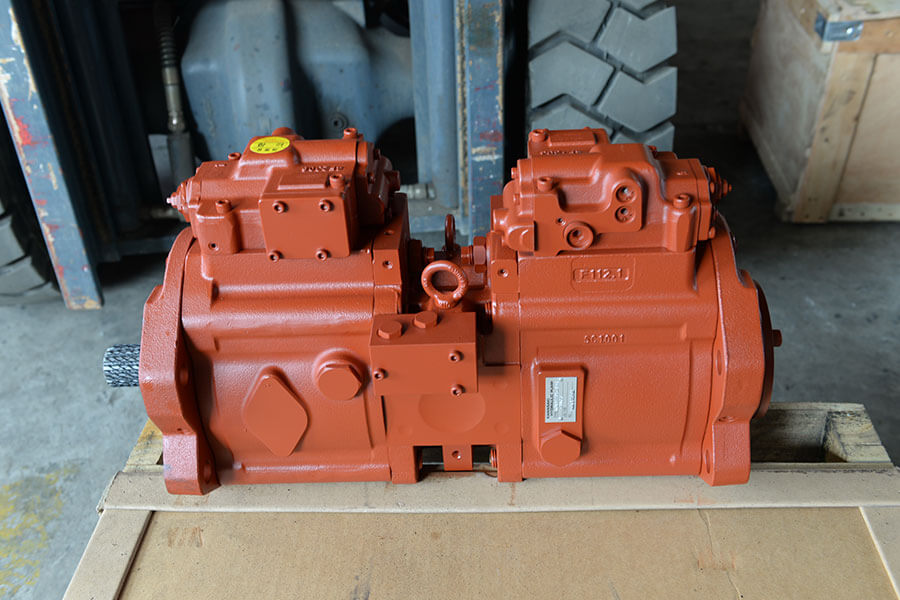

Oil pump

In terms of the hydraulic system, all concrete pumps are equipped with Kawasaki brand oil pumps, ensuring stable pressure output during operation. As a result, the system effectively avoids oil leakage risks, maintains low oil temperature, and delivers smooth switching with minimal impact, guaranteeing reliable and long-term performance.

Control system

The control system of the concrete pump adopts local and remote control, using Siemens or Omron PLC system, safe and stable operation, and the operating language can be customized according to needs.

Concrete pipe

Each concrete pump is standardly equipped with 100 meters of delivery pipeline, ensuring smooth and efficient concrete transportation for most construction projects. If additional delivery distance is required, customers are welcome to contact us to purchase extra pipelines, providing greater flexibility to meet different site conditions.

High-quality accessories

All concrete pump components are manufactured in strict accordance with industry standards. In addition, each unit is delivered with essential spare parts to ensure smooth commissioning and convenient maintenance after installation.

Parameters of Concrete Pumps

Concrete pumps are equipped with different power sources and accessories according to different models, and the specific parameters need to be determined according to actual conditions.

| Model | HBS40/HBTS40 | HBS50/HBTS50 | HBS60/HBTS60 | HBS80/HBTS80 | HBS90/HBTS90 |

| Max. Theoretic capacity(m³/h) | 40 | 50 | 60/46 | 85/50 | 90/55 |

| Max, Theoretic pressure(Mpa) | 10 | 12 | 13/6.3 | 15.7/8.6 | 18/9.3 |

| Motor/diesel engine power(kw) | 45/66 | 55/82 | 90/129 | 110/176 | 110/176 |

| Maximum vertical distance(mm) | 120 | 150 | 200 | 250 | 300 |

| Maximum horizontal distance(mm) | 250 | 300 | 500 | 800 | 1000 |

| Disribution valve type | S valve | ||||

| Hydraulic oil circuit type | Open Circuit | ||||

| Specification of concrete cylinder(mm) | Ø160×1000 | Ø180×1200 | Ø200×1800 | Ø200×1800 | Ø200×1800 |

| Specification of main oil cylinder(mm) | Ø100×1000 | Ø125×1200 | Ø140×1800 | Ø140×1800 | Ø140×1800 |

| Oil tank capacity(L) | 300 | 300 | 420 | 420 | 580 |

| Hopper capacity(L) | 600 | 600 | 600 | 600 | 800 |

| Max. Aggregate diameter(mm) | Slick scree: 40 | Slick scree: 50 | |||

| Scree: 30 | Scree: 40 | ||||

| Dimension (LxWxH)(mm) | 4500×1750×1600 | 4800×1800×1650 | 5800×2000×1750 | 5800×2000×1800 | 6000×2000×1800 |

| Overall weight(kg) | 3200 | 3500 | 5500 | 5800 | 6500 |

| Pulling speed(km/h) | ≤8 | ||||

Application areas of Concrete Pumps

Concrete pumps play a vital role in modern construction and engineering projects. By delivering high pumping efficiency, they significantly reduce labor requirements while saving both time and manpower. Moreover, with simple operation and reliable performance, concrete pumps ensure fast, continuous, and stable concrete placement.

As a result, the construction industry widely applies concrete pumps in urban development, bridge construction, power plants, and other energy infrastructure projects, making them essential equipment for improving construction efficiency and overall project quality.

Choosing the right supplier means choosing the future

Before starting your concrete batching plant project, you need to choose a suitable supplier to provide you with long-term support and service. Henan Hengyuan is undoubtedly one of your best choices.

Years of manufacturing experience, standardized manufacturing process, and excellent machine quality.

Professional technical team, constantly optimizing machine details to meet customer needs.

Years of foreign trade sales experience, familiar with the delivery process, fast and efficient.

Factory direct sales price, all machines are manufactured by independent factories.

Customizable solution details to meet your actual production customization needs.

Control system with exclusive operating language, convenient and fast daily operation.

Installation solution is provided, and installation design is carried out according to the actual site size.

Technical guidance, providing engineers with remote technical guidance or on-site guidance.

Henan Hengyuan’s machines are shipped all over the world

As a foreign trade factory with many years of experience in loading containers, our machines and equipment are shipped all over the world.

Ready to start your project?

Are you ready to start your own project, but don’t know how to proceed? You can contact us to leave your requirements and details, and we will provide you with a detailed engineering solution.

Study local market demand and peer sales data. Design and plan relevant project budgets and plans.

Determine the size and location of the project site and apply for relevant project licenses.

Select a suitable equipment supplier and install and test the equipment effect.

After testing, the project will be officially put into operation, and production data statistics will be prepared to facilitate the calculation of profits.

Carry out long-term maintenance and care of machinery and equipment, and replace wearing parts regularly.

Our client case site

Henan Hengyuan is a professional concrete batching plant manufacturer, and its concrete batching plants are sold in more than 100 countries around the world.

More products

We not only produce various concrete batching plants, but also various types of concrete pumps, concrete mixing pumps, stabilized soil mixing plants and various concrete mixers.