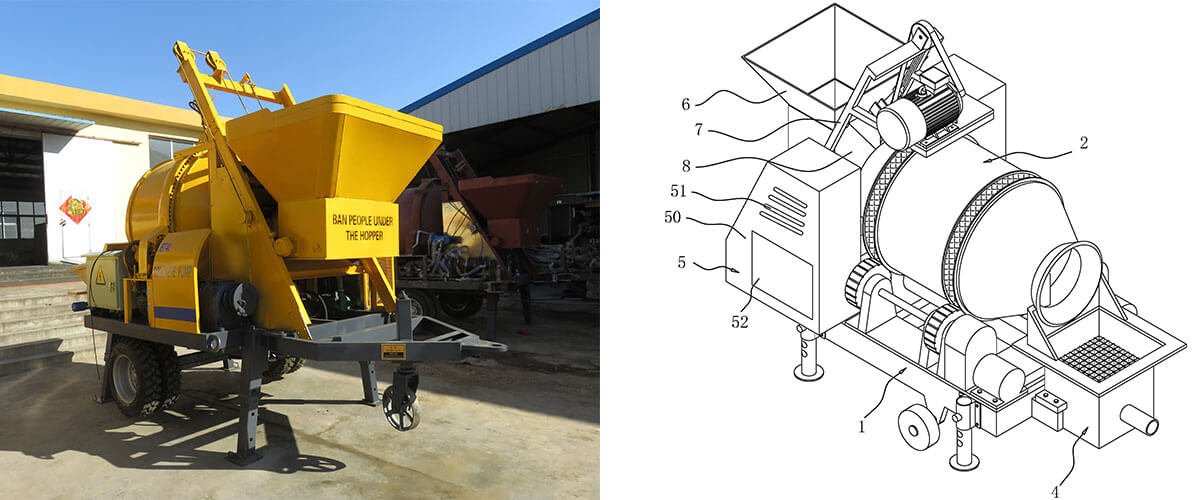

Concrete Mixer Pump

Concrete mixing pump is a multifunctional construction machinery that integrates concrete mixing and conveying functions. It adopts a fully hydraulic pumping system and has the characteristics of large concrete pouring volume, stable performance, small size, and small operating space. It is suitable for small and medium-sized house buildings with a height of 2 meters to 100 meters, as well as various projects such as mine caves, highway and railway tunnels, water conservancy and hydropower projects, and geological disaster slope protection.

Types of Concrete Mixer Pump

Concrete mixing pumps are widely used in various types of construction projects, including high-rise buildings, bridge construction, highway construction, tunnel construction, etc. The machine has high efficiency, high construction quality, low labor demand, easy mobility, and can adapt to various construction plans and site conditions.

Motor-powered concrete mixer pump: driven by a motor, it can pump self-mixed concrete and commercial concrete.

Diesel engine-powered concrete mixer pump: driven by a diesel engine, it can pump self-mixed concrete and commercial concrete.

Twin-shaft concrete mixer pump: using a mandatory twin-shaft concrete mixer, the finished product has high quality.

Pan-type concrete mixer pump: using a pan-type concrete mixer, it has a large output.

Concrete mixer pump with batching machine: a simple batching machine is equipped with a mixer and a pumping machine to meet a variety of scenarios.

Working principle of Concrete Mixer Pump

The working principle of a concrete mixing pump can be divided into two main parts: mixing and conveying. Add raw materials such as cement, sand, and water into the mixing tank and mix them evenly through the agitator to form the required concrete. The mixed concrete is conveyed to the conveying pipe through the concrete pump using the hydraulic system. The concrete reaches the designated location through the conveying pipe and the pouring is completed.

The composition of Concrete Mixer Pump

The main components of a concrete mixer pump include: Power system: Provides power for the whole machine, and can be selected from diesel engines or electric motors. Mixing system: Responsible for mixing raw materials into concrete, common types include drum mixers, twin-shaft mixers and planetary mixers. Pumping system: Transports concrete to a designated location, mainly composed of pumps, pipelines and control systems.

Motor

The motor of the concrete mixing pump adopts an internationally renowned brand and can be replaced with Siemens according to customer needs, and the voltage can be changed according to the customer’s on-site voltage.

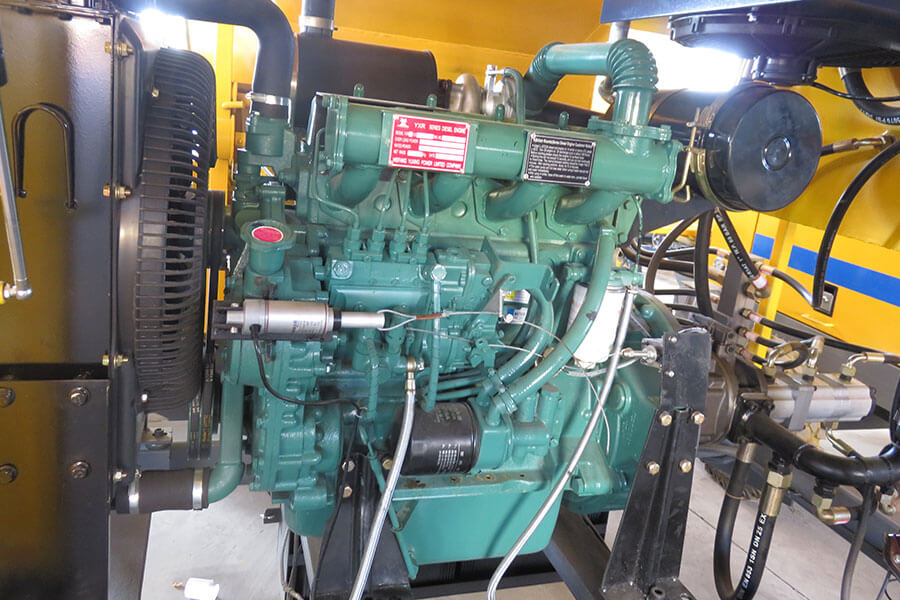

Diesel engine

The diesel engine of the concrete mixing pump adopts a well-known domestic brand and can be replaced with Cummins or other brands according to customer needs. The oil pressure is stable during operation.

Mixer machine

The main mixer can be selected according to actual needs. Common types include drum mixer, twin-shaft mixer and planetary mixer.

Control system

The control system of the concrete mixing pump adopts local and remote control, using Siemens or Omron PLC system, safe and stable operation, and the operating language can be customized according to needs.

Concrete pipe

We are equipped with 100 meters of delivery pipeline for each concrete mixing pump. If you need more, you can also contact us to purchase.

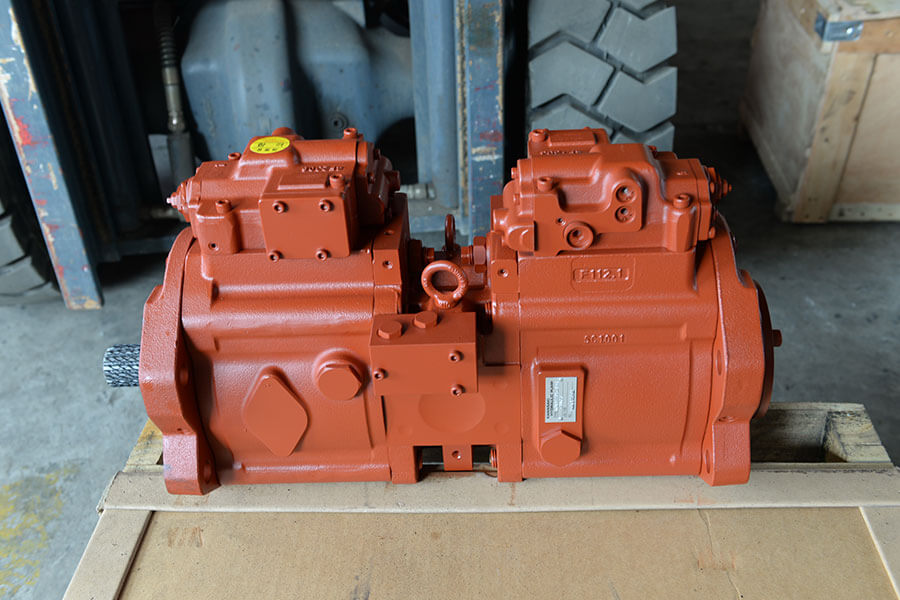

High-quality accessories

The concrete mixing pump parts we produce are all internationally renowned brands, with worry-free quality, and replacement parts are provided before leaving the factory.

Parameters of Concrete Mixing Pump

Concrete mixing pumps are equipped with different power sources and accessories according to different models, and the specific parameters need to be determined according to actual conditions.

| Model | JBS30/JBTS30 | JBS40/JBTS40 | Pump with twinshaft mixer | With pan mixer | Mixer pump with batching machine |

| Theoretical capacity(m³/h) | 30 | 40 | 40 | ||

| Max. concrete pumping pressure(Mpa) | 10 | 10 | 10 | ||

| Power type | Motor/Diesel | Motor/Diesel | Motor | ||

| Main electric motor(kw) | 37/82 | 45/82 | 45/82/129 | ||

| Main oil pump | Kawasaki | Kawasaki | Kawasaki | ||

| Main oil pump capacity(ml/min) | 71 | 112 | 112 | ||

| Theoretical delivery distance(m) | 120/350 | 160/500 | 160/500 | ||

| Hopper capacity(L) | 550 | 550 | 550 | ||

| Max. aggregate diameter(mm) | 20/30 | 30/40 | 30/40 | ||

| Inside diameter of delivery pipe(mm) | 125 | 150 | Φ150 | ||

| Loading capacity of the mixer(L) | 560 | 720 | 720 | ||

| Unloading capacity of the mixer(L) | 350 | 450 | 450 | ||

| Mixing motor(kw) | 5.5 | 5.5 | 5.5 | ||

| Hoisting motor(kw) | 4.5 | 4.5 | 4.5 | ||

| Dimension(LxWxH)(mm) | 4500x2200x2800 | 4800x2200x2800 | 4800x2200x2800 | ||

| Total weight(kg) | 5000 | 5500 | 5500 | ||

Application areas of Concrete Mixing Pump

Concrete mixer pumps are widely used in various construction projects, including high-rise buildings: transporting concrete to high places. Bridge construction: transporting concrete to bridge piers, beams and other parts. Highway construction: transporting concrete to road surfaces, bridges and culverts. Tunnel construction: transporting concrete to tunnel walls, vaults and other parts.

Choosing the right supplier means choosing the future

Before starting your concrete batching plant project, you need to choose a suitable supplier to provide you with long-term support and service. Henan Hengyuan is undoubtedly one of your best choices.

Years of manufacturing experience, standardized manufacturing process, and excellent machine quality.

Professional technical team, constantly optimizing machine details to meet customer needs.

Years of foreign trade sales experience, familiar with the delivery process, fast and efficient.

Factory direct sales price, all machines are manufactured by independent factories.

Customizable solution details to meet your actual production customization needs.

Control system with exclusive operating language, convenient and fast daily operation.

Installation solution is provided, and installation design is carried out according to the actual site size.

Technical guidance, providing engineers with remote technical guidance or on-site guidance.

Henan Hengyuan’s machines are shipped all over the world

As a foreign trade factory with many years of experience in loading containers, our machines and equipment are shipped all over the world.

Ready to start your project?

Are you ready to start your own project, but don’t know how to proceed? You can contact us to leave your requirements and details, and we will provide you with a detailed engineering solution.

Study local market demand and peer sales data. Design and plan relevant project budgets and plans.

Determine the size and location of the project site and apply for relevant project licenses.

Select a suitable equipment supplier and install and test the equipment effect.

After testing, the project will be officially put into operation, and production data statistics will be prepared to facilitate the calculation of profits.

Carry out long-term maintenance and care of machinery and equipment, and replace wearing parts regularly.

Our client case site

Henan Hengyuan is a professional concrete batching plant manufacturer, and its concrete batching plants are sold in more than 100 countries around the world.

More products

We not only produce various concrete batching plants, but also various types of concrete pumps, concrete mixing pumps, stabilized soil mixing plants and various concrete mixers.