Concrete Auxiliary Equipment

Concrete auxiliary equipment refers to the machines that are essential for producing concrete, in addition to other equipment such as the mixing machine.

Types of Concrete Auxiliary Equipment

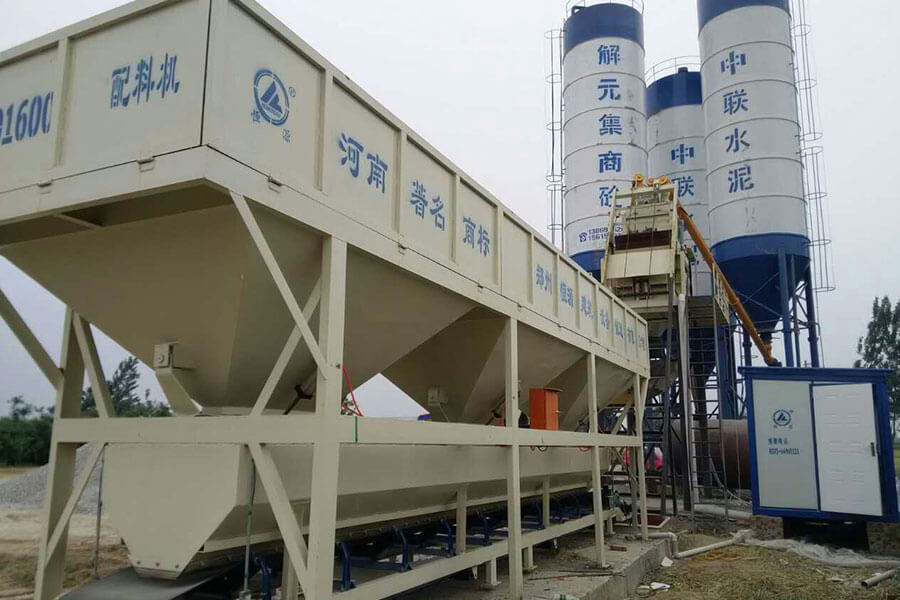

Concrete auxiliary equipment refers to various mechanical equipment used in the production, transportation and process of concrete. These equipment not only improve the construction efficiency, but also ensure the quality of concrete.

Aggregate batching machine: automated equipment for quantitative distribution of various materials such as sand and gravel.

Screw conveyor: a machine that uses a motor to drive the screw to rotate and push materials to achieve the purpose of transportation.

Cement silo: equipment for storing various bulk building materials such as cement and fly ash.

Working principle

Concrete auxiliary equipment is mainly used in the concrete production process. For example, the aggregate batching machine is used to weigh and batch various sand and gravel aggregates, the screw conveyor is used to transport various cement and other materials, and the cement silo is a device for storing bulk cement.

Details of concrete auxiliary equipment

Concrete auxiliary equipment can be divided into batching equipment, conveying equipment and storage equipment according to different working purposes. Common ones include aggregate batching machines, screw conveyors and cement silos.

Parameters of Concrete Auxiliary Equipment

Concrete mixers have different parameters according to different power and different types. The specific parameters need to be determined according to actual conditions.

| Model | PLD800 | PLD1200 | PLD1600 | PLD2400 | PLD3200 | PLD4800 |

| Weighing hopper capacity (L) | 800 | 1200 | 1600 | 2400 | 3200 | 4800 |

| Discharging hopper capacity (m³) | 2*2.5 | 3*5 | 3*5 | 4*17 | 4*23 | 4*30 |

| Productivity (m³/h) | 48 | 56 | 75 | 150 | 200 | 300 |

| Batching accuracy | ±2% | ±2% | ±2% | ±2% | ±2% | ±2% |

| Maximum weighing value (kg) | 3000 | 3000 | 3000 | 4500 | 4500 | 6000 |

| Number of batchable materials | 2-3 | 2-4 | 2-4 | 2-4 | 2-4 | 2-4 |

| Feeding height (mm) | 2450 | 2950 | 2950 | 3700 | 4000 | 5000 |

| Feeding belt speed (m/s) | 1.6 | 1.6 | 1.6 | 1.6 | 1.6 | 2 |

| Power (kw) | 3*3 | 4*3 | 4*3 | 11 | 11 | 15 |

| Machine weight (kg) | 2450 | 4500 | 4500 | 8500 | 10200 | 14000 |

| Dimensions (mm) | 5600*1650*2950 | 9400*2100*3450 | 9400*2100*3450 | 14500*3250*4000 | 14500*3450*4500 | 16500*3500*4750 |

| Model | LSY160 | LSY200 | LSY250 | LSY300 |

| Spiral diameter (mm) | 160 | 193 | 250 | 300 |

| Conveying length (m) | 2.5-6 | 4.5-12 | 6-9 | 6-9 |

| Spiral speed (r/min) | 100 | 209 | 209 | 174 |

| Shell diameter (mm) | 194 | 219 | 273 | 325 |

| Working angle (°) | ≤20 | ≤45 | ≤45 | ≤45 |

| Conveying capacity (t/h) | 25 | 35 | 50 | 75 |

| Motor model | Y-132M-4 | Y-160M-4 | Y-160L-4 | Y-180L-4 |

| Motor power (kw) | 3-7.5 | 4-11 | 7.5-15 | 11-22 |

| Model | Tank diameter (m) | Tank height (m) | Total tank height (m) |

| SNC30T | 2.5 | 4.8 | 11.4 |

| SNC50T | 3 | 5.4 | 12 |

| SNC80T | 3 | 9 | 15.6 |

| SNC100T | 3 | 11.4 | 18 |

| SNC150T | 3 | 23.5 | 29 |

| SNC200T | 4.5 | 18.6 | 25.2 |

| SNC300T | 4.5 | 24.6 | 29.5 |

| SNC500T | 6 | 22.2 | 28.8 |

Application areas of Concrete Auxiliary Equipment

Concrete auxiliary machinery is mainly used to assist concrete mixers in producing concrete, and is often used in various concrete batching plants. Choosing appropriate concrete auxiliary equipment can not only improve work efficiency, but also improve the quality of concrete.

Choosing the right supplier means choosing the future

Before starting your concrete batching plant project, you need to choose a suitable supplier to provide you with long-term support and service. Henan Hengyuan is undoubtedly one of your best choices.

Years of manufacturing experience, standardized manufacturing process, and excellent machine quality.

Professional technical team, constantly optimizing machine details to meet customer needs.

Years of foreign trade sales experience, familiar with the delivery process, fast and efficient.

Factory direct sales price, all machines are manufactured by independent factories.

Customizable solution details to meet your actual production customization needs.

Control system with exclusive operating language, convenient and fast daily operation.

Installation solution is provided, and installation design is carried out according to the actual site size.

Technical guidance, providing engineers with remote technical guidance or on-site guidance.

Henan Hengyuan’s machines are shipped all over the world

As a foreign trade factory with many years of experience in loading containers, our machines and equipment are shipped all over the world.

Ready to start your project?

Are you ready to start your own project, but don’t know how to proceed? You can contact us to leave your requirements and details, and we will provide you with a detailed engineering solution.

Study local market demand and peer sales data. Design and plan relevant project budgets and plans.

Determine the size and location of the project site and apply for relevant project licenses.

Select a suitable equipment supplier and install and test the equipment effect.

After testing, the project will be officially put into operation, and production data statistics will be prepared to facilitate the calculation of profits.

Carry out long-term maintenance and care of machinery and equipment, and replace wearing parts regularly.

Our client case site

Henan Hengyuan is a professional concrete batching plant manufacturer, and its concrete batching plants are sold in more than 100 countries around the world.

More products

We not only produce various concrete batching plants, but also various types of concrete pumps, concrete mixing pumps, stabilized soil mixing plants and various concrete mixers.