Drum Concrete Mixer

The drum mixer is also called a self-falling double-cone reverse discharging concrete mixer. It mixes in the forward direction and discharges in the reverse direction. It can mix plastic and semi-dry hard concrete.

The mixing drum of this machine is driven by a gear ring or a rubber roller friction drive, with a compact structure and stable operation. It is suitable for general construction sites, roads, bridges, hydropower and other projects and small and medium-sized concrete component plants.

Application scope of Drum Concrete Mixers

Construction sites: used for concrete mixing in general construction sites.

Road and bridge projects: suitable for concrete mixing in road and bridge projects.

Small and medium-sized concrete component plants: suitable for concrete mixing in small and medium-sized concrete component plants.

Other fields: such as water conservancy projects, infrastructure construction, etc.

Different capacity of Drum Concrete Mixers

Drum concrete mixers can be divided into friction transmission and ring gear transmission according to different transmission methods. Each type of mixer is divided into multiple models according to different hourly production capacity. Common models are: JZC250, JZC350, JZC500, JZC750 and JZM350, JZM500, JZM750, etc.

Working process of Drum Concrete Mixers

Put the material to be mixed into the roller and start the equipment. The roller starts to rotate, and the materials are gradually mixed together during the rolling process. While rotating, the roller will also flip to ensure that the materials are evenly distributed inside. When the mixing reaches the predetermined requirements, the discharge port can be opened to discharge the mixed materials.

Components of Drum Concrete Mixers

Mixing drum: The mixing drum is the main working part of the drum mixer. It is usually a double-conical structure. High and low blades are welded inside the drum, which are at specific angles to the mixing axis.

Feeding mechanism: The feeding system consists of a hoisting mechanism, a feeding rack, a hopper, a feeding funnel, etc. The brake motor can ensure that the hopper can stop reliably at any position when running at full load.

Water supply system: The water supply system consists of an electric motor, a water pump, a regulating valve, a water suction valve and a pipeline.

Transmission system: The transmission system usually includes a reduction box and a transmission gear. The forward and reverse rotation of the mixing drum is achieved by the motor reversing.

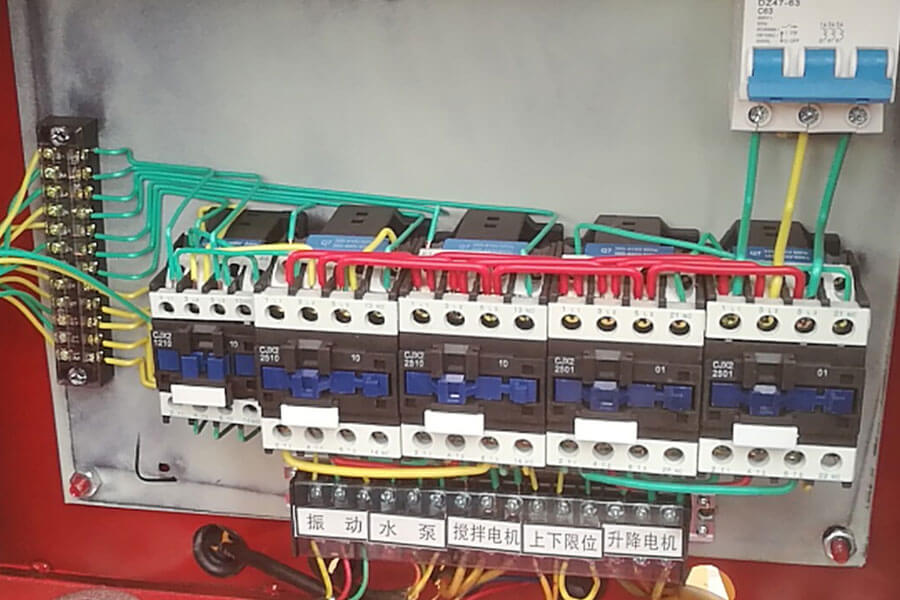

Electrical control system: A fully automatic control system that controls the operation of each part.

Feeding mechanism

Machine shell

Transmission mechanism

Control system

Advantages of Drum Concrete Mixer

Easy installation foundation: The whole machine is a frame structure, and only the ground needs to be leveled.

Easy disassembly and transfer: The high integrity of the equipment is convenient for storage or transfer transportation at the construction site.

High integrity: Except for the finished material stacking belt conveyor, all systems are integrated into an overall frame, which not only ensures the integrity of the equipment but also leaves appropriate maintenance and inspection space.

High working reliability: convenient and flexible operation, easy discharging, easy cleaning of the mixing tank and direct feeding, economical to use.

Are you ready to start your project?

As a professional construction machinery manufacturer, Henan Hengyuan not only has a professional technical team, but also has excellent machinery quality. The construction machinery equipment produced by Henan Hengyuan welcomes customers from all over the world to purchase.

1.We will recommend the corresponding machine to you according to your production needs.

2.We will calculate the site and factory area according to your production requirements and give you factory construction suggestions.

3.Our professional technical engineers will draw professional installation plans and machine layout drawings for you.

4.If you encounter any problems during production, we will send professional engineers to connect via video or solve them on site.

Get ready to contact us

If you are ready to start your project, please contact us immediately. Tell us your needs and we will provide you with the most suitable production plan and quotation.