Mobile Stabilized Soil Mixing Plant

Building on the technology of the combined detachable stabilized soil mixing station, this mobile plant evolved to offer greater flexibility. Specifically, its twin-shaft mixing system actively combines various materials—such as quicklime, slaked lime, soil, sand, gravel, fly ash, and cement—into high-quality stabilized soil.

Application scope of Mobile Stabilized Soil Mixing Plants

Different capacity of Mobile Stabilized Soil Mixing Plants

Mobile stabilized soil mixing stations can be divided into various models according to different production capacities. Common models include YWBZ300, YWBZ400, YWBZ500, YWBZ600, YWBZ700, YWBZ800, etc.

YWBZ300 mobile Stabilized Soil Mixing Station

yWBZ400 mobile Stabilized Soil Mixing Station

YWBZ500 mobile Stabilized Soil Mixing Station

YWBZ600 mobile Stabilized Soil Mixing Station

YWBZ700 mobile Stabilized Soil Mixing Station

YWBZ800 mobile Stabilized Soil Mixing Station

Working process of Mobile Stabilized Soil Mixing Plants

First, the feeding equipment loads pre-selected materials like cement, crushed sand, gravel, and soil into the aggregate bin of the batching machine.

Next, the electronic belt scale accurately measures the aggregate. Once weighed, the system sends it to the aggregate conveyor below.

Simultaneously, the powder distribution system transports powder materials via a spiral conveyor path.

Finally, all these materials converge and are fed together into the mixer for thorough, uniform blending.

Components of Mobile Stabilized Soil Mixing Plant

The mobile stabilized soil mixing station is mainly composed of a mixing system, a batching system, a conveying system, a control system and a cement silo.

1. Batching System:

This system is responsible for the accurate measurement and transportation of various aggregates. It integrates components such as the aggregate silo, weighing belt conveyor, and aggregate belt conveyor.

2. Powder System:

Specifically handling powders like cement and lime, the powder system achieves precise measurement and transfer. It comprises a cement silo, powder metering equipment, and screw conveyors.

3. Water Supply System:

To ensure precise water control, this system manages the water supply through a tank, submersible pump, pipelines, a pressure reducing valve, and a flow meter.

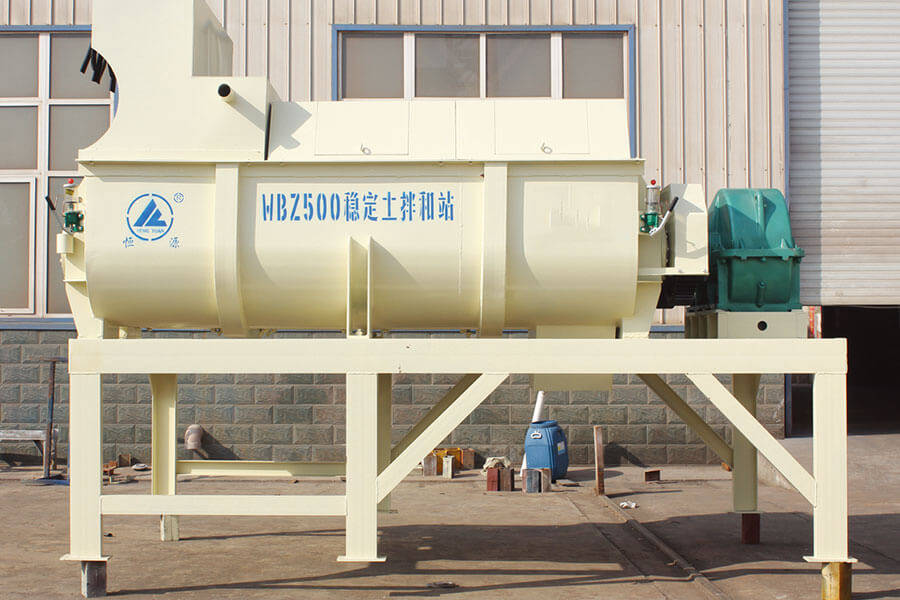

4. Mixing System:

At the heart of production, a double-horizontal shaft forced mixer delivers uniform and highly efficient mixing.

5. Storage System:

For the temporary storage and transfer of mixed materials, the storage system employs a storage silo and an inclined belt conveyor.

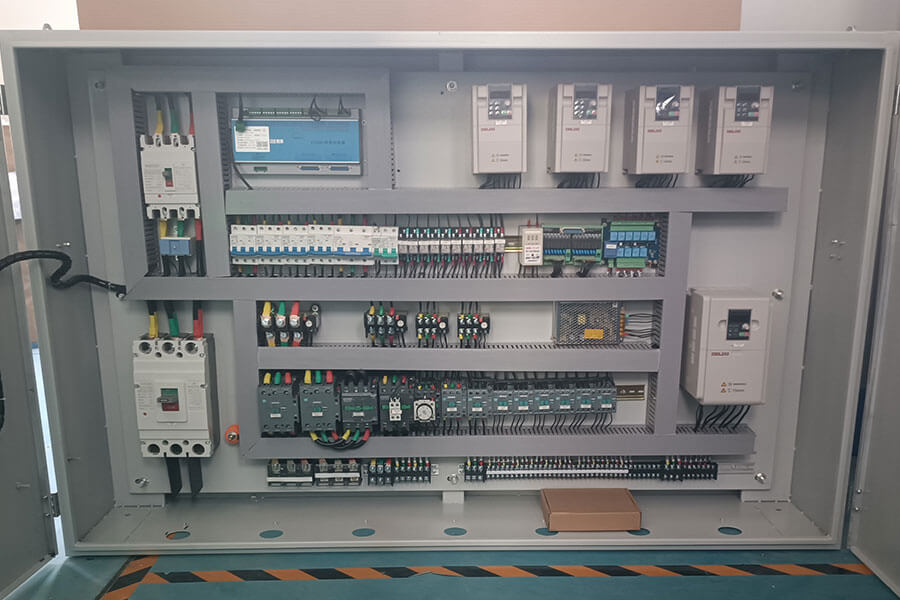

6. Electrical Control System:

Orchestrating the entire plant, an industrial microcomputer-based automatic control system enables functions such as automated operation, formula storage, and fault alarm.

batching system

mixing system

Finished product bin

control system

Advantages of Mobile Stabilized Soil Mixing Plant

Strong mobility: The integrated structural design greatly improves the mobility of the equipment.

Efficient production: The double-horizontal shaft forced continuous mixing main machine has high production efficiency.

Flexible and applicable: It can mix gravel stabilized soil, ash stabilized soil, etc., and is suitable for various projects.

High degree of automation: Equipped with a computer control system, manual and automatic selection can be performed.

Energy saving and consumption reduction: The frequency conversion speed regulation method or electromagnetic speed regulation method is adopted, and the operation is reliable.

Convenient maintenance: The seamless vulcanized joint ring belt or large-angle corrugated sidewall belt is adopted, and the operation is stable.

Are you ready to start your project?

As a professional construction machinery manufacturer, Henan Hengyuan not only has a professional technical team, but also has excellent machinery quality. The construction machinery equipment produced by Henan Hengyuan welcomes customers from all over the world to purchase.

1.We will recommend the corresponding machine to you according to your production needs.

2.We will calculate the site and factory area according to your production requirements and give you factory construction suggestions.

3.Our professional technical engineers will draw professional installation plans and machine layout drawings for you.

4.If you encounter any problems during production, we will send professional engineers to connect via video or solve them on site.

Get ready to contact us

If you are ready to start your project, please contact us immediately. Tell us your needs and we will provide you with the most suitable production plan and quotation.