Pan Type Concrete Mixer Pump

The pan concrete mixer pump is a new type of concrete mixing and pumping machine that uses a disc mixer as the mixing host. The mixing process is more convenient and less prone to clogging. Different models can be customized according to customer needs.

The pan concrete mixer pump is an efficient and reliable concrete delivery equipment suitable for various complex construction environments. Its versatility and high efficiency make it an ideal choice for the construction industry.

Application scope of Pan Type Concrete Mixer Pumps

High-rise buildings: used to pump concrete to the upper floors of high-rise buildings.

Infrastructure projects: used in the construction of roads, bridges, tunnels and other infrastructure projects.

Residential buildings: used for residential buildings, such as concrete pouring for house foundations, patios and driveways.

Remote or difficult-to-access locations: more convenient in places with inconvenient transportation, such as remote construction sites or areas with complex terrain.

Different capacity of Concrete Mixer Pumps

The types and specifications of disc concrete mixer pumps are distinguished by the production capacity of the mixing main unit, and the corresponding mixing main unit can be selected according to the production needs of users.

The specific parameters and specifications can be changed according to actual production needs, and the color and appearance of the whole machine can be customized as needed.

Concrete Mixer Pumps

Concrete Mixer Pumps

Working process of Pan Concrete Mixer Pump

After the raw materials are stirred and mixed by a pan mixer to form qualified concrete, they are transported to the designated location via a concrete pump system.

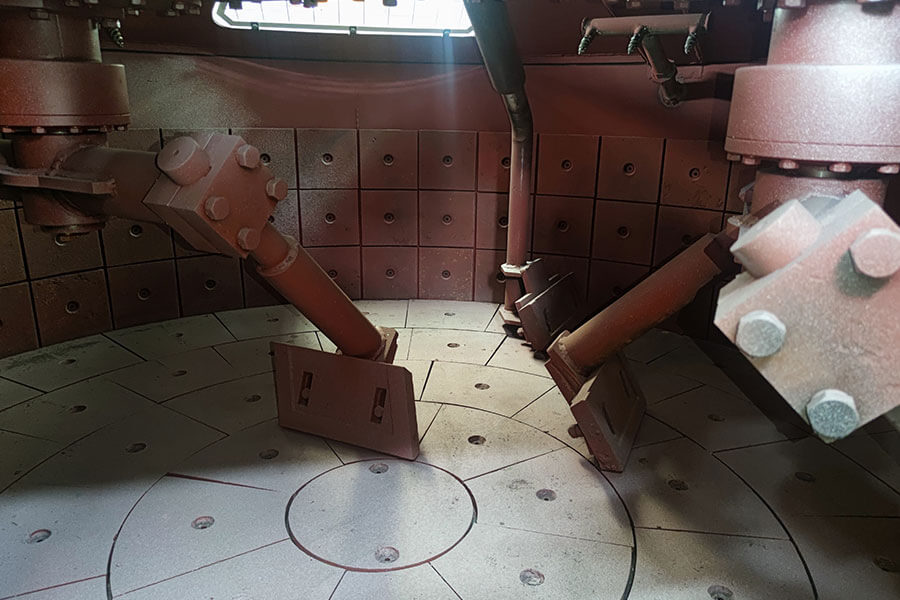

Components of Pan Type Concrete Mixer Pump

Disk stirring device: includes one or more rotating stirring disks with stirring blades installed on them.

Transmission device: responsible for transmitting power to the stirring disk so that it can rotate at a predetermined speed. Common transmission methods include belt drive, gear drive and coupling drive.

Discharging device: used to discharge the mixed materials from the mixer. Common unloading methods include pneumatic unloading and electric unloading.

Water supply system: provides precise water volume control for the mixing process to ensure the quality of the mixed materials.

Hydraulic system: provides power for the pumping system, including hydraulic pumps, valve groups, accumulators, hydraulic motors and other hydraulic components.

Electrical control system: used to control the operation of various parts of the mixer, including the start, stop and speed adjustment of the mixing motor, the opening and closing control of the unloading device, the water volume control of the water supply system, etc.

hopper

mixing system

Mobile frame

Control system

Advantages of Pan Type Concrete Mixer Pump

Good mixing effect: The disc mixing system can achieve efficient mixing effect and ensure the uniformity and quality of concrete.

High production efficiency: The mixing speed is fast and the production efficiency is high, which can meet the needs of large-scale construction.

Convenient maintenance: The maintenance of the mixer is relatively simple and the maintenance cost is low.

Low energy consumption: The mixer has low energy consumption, energy saving and environmental protection.

Are you ready to start your project?

As a professional construction machinery manufacturer, Henan Hengyuan not only has a professional technical team, but also has excellent machinery quality. The construction machinery equipment produced by Henan Hengyuan welcomes customers from all over the world to purchase.

1.We will recommend the corresponding machine to you according to your production needs.

2.We will calculate the site and factory area according to your production requirements and give you factory construction suggestions.

3.Our professional technical engineers will draw professional installation plans and machine layout drawings for you.

4.If you encounter any problems during production, we will send professional engineers to connect via video or solve them on site.

Get ready to contact us

If you are ready to start your project, please contact us immediately. Tell us your needs and we will provide you with the most suitable production plan and quotation.