Screw Conveyor

Concrete screw conveyor is a kind of equipment specially used for conveying concrete, which is widely used for continuous conveying between equipment such as concrete mixing plants, concrete mixer trucks and concrete pumps.

It can convey horizontally, inclined or vertically, and has the advantages of simple structure, small cross-sectional area, good sealing, convenient operation, easy maintenance, and convenient closed transportation.

Application scope of Screw Conveyors

Concrete screw conveyors serve a key role in several critical scenarios within the concrete industry.

Primarily, they are widely used in concrete mixing stations to convey powder materials such as cement and fly ash.

Specifically, they facilitate the continuous transfer of materials between mixer trucks and the batching station.

Additionally, they handle material conveyance between concrete pumps and the actual construction site.

Different capacity of Screw Conveyors

Concrete screw conveyors can be divided into various models according to different cylinder diameters and conveying lengths. Common models include LSY160, LSY200, LSY250, LSY300, etc.

Screw conveyors of different sizes and lengths can be customized according to actual customer needs.

LSY160 Screw Conveyor

LSY200 Screw Conveyor

LSY250 Screw Conveyor

LSY300 Screw Conveyor

Working process of Screw Conveyor

Essentially, the concrete screw conveyor operates by using its rotating spiral blades to push materials forward for conveyance.

Specifically, as the screw shaft rotates, the spiral blades actively push against the materials. Due to gravity and the friction between the materials and the trough wall, the materials cannot rotate with the shaft but are forced to slide forward along the bottom of the conveyor trough.

The mechanism is similar to how a nut translates linearly along a rotating screw without itself rotating.

Components of Screw Conveyor

The concrete screw conveyor comprises the following key components, each playing a specific role in its operation:

1. Drive Device:

At the core of this system is the drive device, which combines a motor and a reducer to provide the necessary power for operation.

2. Casing:

Encasing these internal components, the casing serves to protect them and prevent material leakage during conveyance.

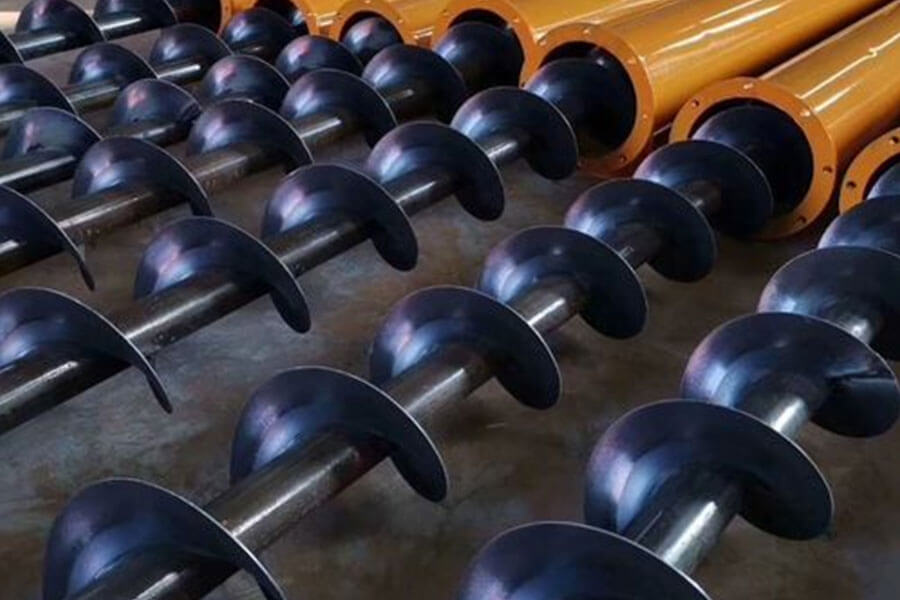

3. Screw Shaft:

Extending through the casing is the screw shaft. It is fitted with spiral blades and is primarily responsible for moving the materials.

4. Spiral Blades:

Fixed along this shaft, the spiral blades typically feature a variable pitch design. This design enables fast and efficient material conveyance.

5. Feed Port and Discharge Port:

For material handling, the feed port allows materials to enter the conveyor, while the discharge port releases them at the designated point.

transmission device

Machine shell

Screw shaft

Spiral blade

Advantages of Screw Conveyors

1. Efficient Conveying:

Firstly, the screw conveyor delivers efficient conveying capacity, enabling it to transport large volumes of materials within a compact space.

2. Low Energy Consumption:

Moreover, by utilizing the material’s own internal friction to aid in pushing (rather than dragging), the system achieves significant energy savings—consuming up to 50% less electricity compared to a belt conveyor.

3. Excellent Sealing:

Crucially, the fully sealed casing prevents dust escape entirely. This design ensures safe operation and provides highly reliable running performance.

4. Long Service Life & Flexibility:

Furthermore, its flexible layout allows installation on elevated structures, ground level, or in pits. It can be arranged horizontally, on an incline (≤15°), or in a combined horizontal/inclined configuration on a single unit, and supports multi-point feeding and discharging.

5. Low Cost of Use:

Ultimately, the conveyor’s energy-efficient and durable construction, coupled with minimal maintenance needs, leads to low operational costs. This helps ensure the host machine’s normal operation to increase output, reduce consumption, and improve overall efficiency.

Are you ready to start your project?

As a professional construction machinery manufacturer, Henan Hengyuan not only has a professional technical team, but also has excellent machinery quality. The construction machinery equipment produced by Henan Hengyuan welcomes customers from all over the world to purchase.

1.We will recommend the corresponding machine to you according to your production needs.

2.We will calculate the site and factory area according to your production requirements and give you factory construction suggestions.

3.Our professional technical engineers will draw professional installation plans and machine layout drawings for you.

4.If you encounter any problems during production, we will send professional engineers to connect via video or solve them on site.

Get ready to contact us

If you are ready to start your project, please contact us immediately. Tell us your needs and we will provide you with the most suitable production plan and quotation.