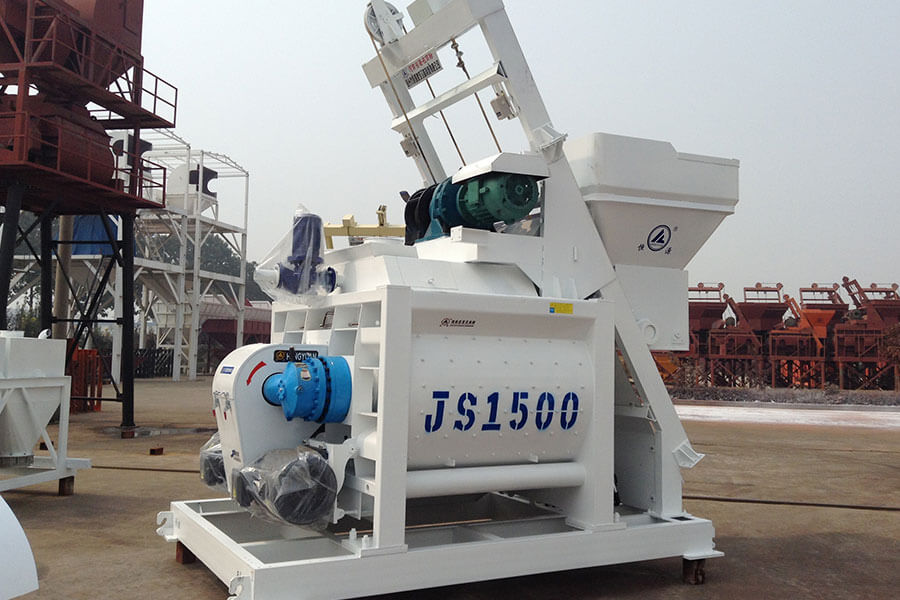

JS1500 Twin Shaft Concrete Mixer

The JS1500 twin-shaft concrete mixer is a high-performance, durable mixing solution widely used in construction projects, large-scale infrastructure works, concrete batching plants, and prefabricated component production.

As a medium-capacity twin-shaft mixer, it delivers fast, uniform mixing and reliably meets the concrete production demands of large-scale and continuous construction operations.

Capacity:≥75m³/h

Warranty: 18 months

Mixer Motor Power: 18.5Kw

Voltage: 220v/380v/415v/440v/480v(50Hz/60Hz)

Structure

The JS1500 twin-shaft concrete mixer is composed of several key components that work together to ensure efficient and stable concrete mixing.

First, the mixing drum features a large-capacity structure with two horizontally arranged rotating shafts. Multiple mixing blades are mounted on the shafts, allowing materials to be thoroughly stirred during operation.

Next, the twin-shaft mixing system adopts a dual-shaft forced mixing design. Each mixing shaft is independently driven by a reducer, which ensures strong mixing intensity and uniform concrete quality.

In addition, the motor and reducer system provides powerful and stable drive performance. The high-power motor transmits torque through the reducer, converting high-speed rotation into the low-speed, high-torque motion required for effective mixing.

Meanwhile, the feeding system enables smooth and efficient material loading. It is usually equipped with a lifting hopper or elevator, making it easy to feed cement, sand, aggregates, and other raw materials into the mixing drum.

After mixing is completed, the discharging system quickly releases the concrete through a reliable discharge outlet, improving production efficiency and reducing waiting time.

Furthermore, the mixer is equipped with an intelligent control system that supports both manual and automatic operation, allowing operators to manage the mixing process conveniently and accurately.

Finally, the frame and support structure, made of high-strength steel, provides excellent stability and durability. Depending on project requirements, the mixer can be configured with either a fixed base or a wheeled chassis.

Working principle

The working principle of the JS1500 twin-shaft concrete mixer consists of three main stages: feeding, mixing, and discharging.

First, during the raw material feeding stage, operators feed cement, sand, aggregates, and water into the mixing drum through the feed port. An electric hoist or belt conveyor usually completes this process, ensuring continuous and efficient material input.

Next, in the mixing stage, the motor starts and transmits power to the reducers, which drive the two horizontal mixing shafts to rotate in opposite directions. The mixing blades forcibly stir the materials, quickly breaking material agglomeration. As a result, the twin-shaft forced mixing system ensures thorough mixing, uniform distribution, and effectively prevents material segregation.

Finally, during the discharging stage, once mixing is complete, the operator controls the discharge mechanism through the control system. The discharge door opens smoothly, allowing the mixed concrete to flow rapidly into transport vehicles or subsequent equipment. This efficient process minimizes waiting time and improves overall production efficiency.

Product Advantages

First, it delivers efficient and uniform mixing. The twin-shaft forced mixing system thoroughly blends all concrete raw materials, effectively eliminating common problems such as segregation and stratification.

In addition, the mixer demonstrates strong adaptability. It easily handles various concrete formulas, including ordinary concrete, dry hard concrete, and wet-mix concrete, meeting diverse project requirements.

Moreover, the high-speed mixing design significantly shortens mixing time, allowing the mixer to achieve fast and efficient production while improving overall output.

At the same time, the intelligent control system simplifies operation. Operators can flexibly adjust mixing time and speed according to actual production needs, reducing labor intensity and operating difficulty.

In terms of reliability, the mixer features excellent structural stability. High-strength steel materials and advanced manufacturing processes ensure stable operation and a long service life, even under continuous heavy-duty conditions.

Furthermore, the equipment emphasizes energy efficiency and environmental protection. High-efficiency motors reduce energy consumption and operating noise, enabling the mixer to comply with modern environmental standards.

Thanks to its durable and wear-resistant design, the JS1500 withstands long-term, high-intensity operation with minimal performance degradation.

Finally, the mixer offers convenient maintenance. Its modular and maintenance-friendly structure allows quick inspection and component replacement, effectively reducing downtime and maintenance costs.

Product Parameters

| Model | JS1500 |

| Discharge capacity (L) | 1500 |

| Feed capacity (L) | 2400 |

| Productivity (m³/h) | ≥75 |

| Maximum aggregate size (mm) | 80/60 |

| Blade speed (r/min) | 25.5 |

| Number of blending blades (pcs) | 2×10 |

| Blade motor model | Y225M-4 |

| Blade motor power (kw) | 18.5 |

| Winch motor model | YEZ180L-4 |

| Winch motor power (kw) | 45 |

| Water pump motor model | KQW65-100I |

| Water pump motor power (kw) | 3 |

| Hopper lifting speed (m/min) | 23 |

| Dimensions (mm) | 9645x3436x9700 |

| Machine weight (kg) | 11130 |