Diesel Engine Powered Concrete Mixer Pump

The diesel-powered concrete mixer pump is a new type of equipment that is driven by a diesel engine and integrates the functions of a concrete mixer truck and a concrete trailer pump. It is mainly used in areas with power shortages or in scenarios where mobile operations are required.

The machine can effectively mix and pump various types of concrete, and can pump concrete over 100 meters high, making it suitable for various construction projects.

Application scope of Diesel Engine Powered Concrete Mixer Pumps

High-rise buildings: Concrete transportation and pouring of high-rise buildings.

Water conservancy projects: Construction of large water conservancy facilities such as dams, levees, and reservoirs.

Airports and docks: Concrete for the construction of airport runways and docks.

Large shopping malls and urban and rural infrastructure: Construction of large shopping malls and urban and rural infrastructure.

Road and bridge construction: Concrete laying on pavements, bridge piers, beams and other parts.

Tunnel and subway construction: Concrete is transported to narrow and difficult-to-reach areas.

Foundation and basement construction: In the foundation and basement foundation, ensure the stability of the foundation and the smooth progress of construction.

Construction in rural and remote areas: Used in rural and remote areas without electricity supply, it can mix and pump concrete on site.

Different capacity of Diesel Engine Powered Concrete Mixer Pumps

The specifications and models of diesel engine-driven concrete mixing pumps are usually distinguished by the production capacity per hour, and common specifications include JBTS30, JBTS40, etc.

These numbers represent the theoretical maximum production capacity of the mixing plant per hour. The larger the number, the greater the production capacity.

Working process of Diesel Engine Powered Concrete Mixer Pump

First, cement, sand, gravel, water, and other raw materials enter the mixing system through the hopper. Here, the mixer thoroughly mixes them to form a uniform concrete mixture. Then, a diesel engine powers a hydraulic pump, which then drives a piston to draw the concrete from the hopper into the delivery cylinders. Finally, the system pumps the concrete through these cylinders directly to the required location at the construction site.

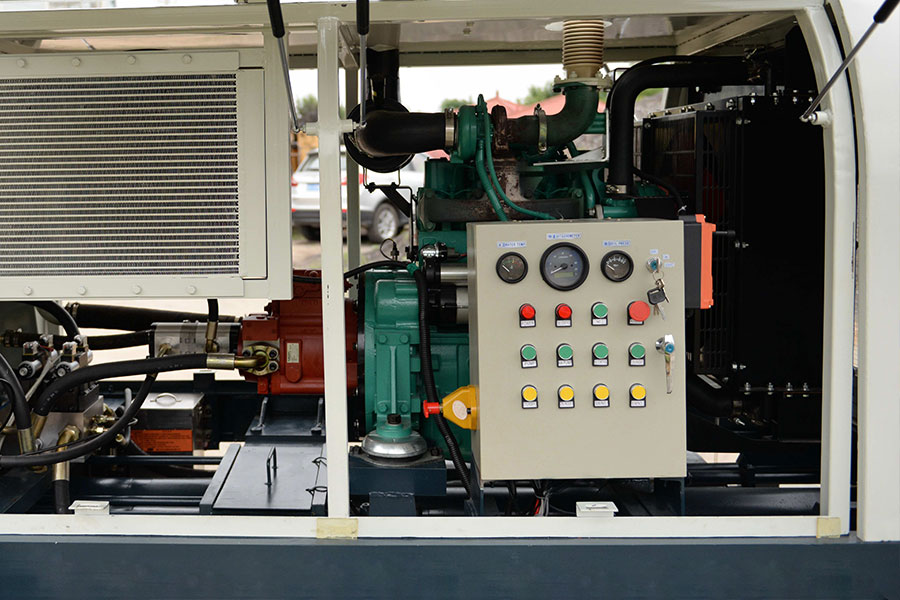

Components of Diesel Engine Powered Concrete Mixer Pump

The diesel engine powered concrete mixing pump is mainly composed of hopper, mixing system, pumping system, hydraulic system, conveying system, control system, diesel engine and other components.

Hopper: used to store concrete raw materials.

Mixing system: responsible for mixing cement, sand, gravel, water and other raw materials evenly to form the required concrete.

Pumping system: including pumps, pipelines and control systems, responsible for conveying concrete to the designated location.

Hydraulic system: provides power to drive the movement of pistons and distribution valves.

Diesel engine: as a power source, drives the operation of the entire system.

hopper

mixing system

Diesel Engine

Control system

Advantages of Diesel Engine Powered Concrete Mixer Pump

Double pump double circuit open hydraulic system: the main pump oil circuit and the S valve rotary oil circuit are independent, which improves the stability and reliability of the system.

Reverse pumping function: can timely clear faults and stop waiting for a moment of material.

Advanced S valve: with automatic compensation of wear gap and good sealing performance.

Wear-resistant plate and wear-resistant ring: made of hard alloy, which prolongs the service life.

Automatic centralized lubrication system: ensure sufficient and effective lubrication during the entire operation process.

Remote automatic control: more convenient and safe operation.

Are you ready to start your project?

As a professional construction machinery manufacturer, Henan Hengyuan not only has a professional technical team, but also has excellent machinery quality. The construction machinery equipment produced by Henan Hengyuan welcomes customers from all over the world to purchase.

1.We will recommend the corresponding machine to you according to your production needs.

2.We will calculate the site and factory area according to your production requirements and give you factory construction suggestions.

3.Our professional technical engineers will draw professional installation plans and machine layout drawings for you.

4.If you encounter any problems during production, we will send professional engineers to connect via video or solve them on site.

Get ready to contact us

If you are ready to start your project, please contact us immediately. Tell us your needs and we will provide you with the most suitable production plan and quotation.