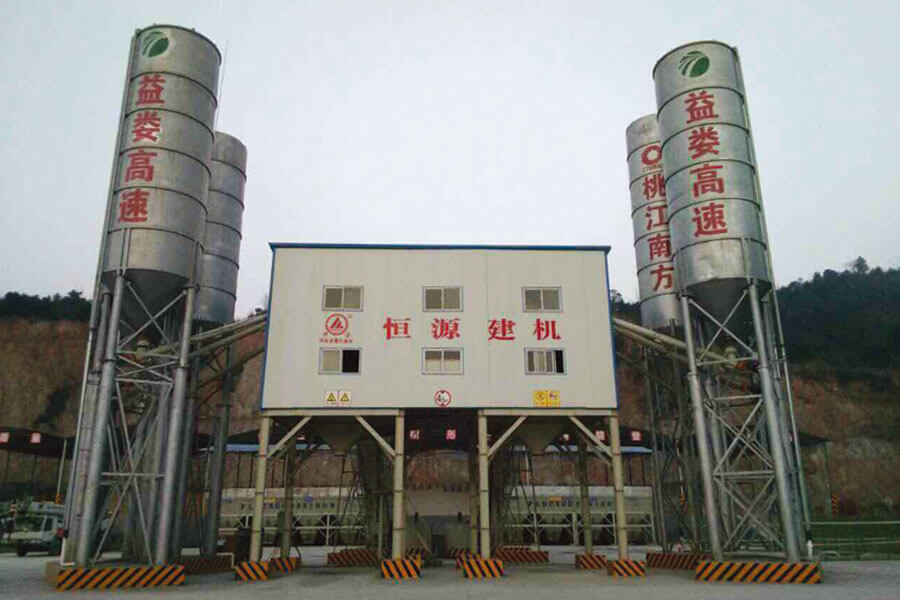

Containerized concrete batching plant VS conventional concrete batching plant

Containerized concrete mixing station VS traditional concrete mixing station: In the wave of rapid development of the construction industry, concrete, as a basic building material, is also constantly innovating its production methods. In recent years, containerized concrete mixing stations have gradually emerged with their flexibility, high efficiency and environmental protection. Compared with traditional traditional concrete mixing stations, they show significant advantages.

Structural design

First, in terms of structural design, Containerized concrete batching plant adopt modular design. The main components of the machine are based on containers, which is convenient for transportation and installation. In contrast, traditional concrete mixing stations usually consist of multiple fixed components. It occupies a large area, has low space utilization, and takes a long time for site preparation and foundation construction. Container sites can be built in a short time and have strong adaptability, especially suitable for temporary engineering projects or construction needs in remote areas.

Production efficiency

Secondly, the production efficiency of container mixing plants is significantly higher than that of traditional mixing plants. The equipment has a high degree of integration, can realize automatic control, and reduce manual intervention. At the same time, container mixing plants can flexibly configure different formulas and production parameters according to project requirements. The production plan can be quickly adjusted to meet different construction requirements. This flexibility is often difficult to achieve in traditional mixing plants.

Production Environment

In terms of environmental protection, the sealed design of the containerized concrete batching station significantly reduces the emission of dust and noise, meeting the high environmental protection standards of modern society. However, conventional concrete batching plants are prone to environmental pollution due to their open design and are subject to increasing regulatory pressure. The environmental performance of containerized sites gives them a competitive advantage in bidding and project approval.

Cost Control

In addition, containerized concrete batching plants also excel in cost control. Although the initial investment may be slightly higher, due to its fast installation and commissioning time, the construction period can be shortened, thereby reducing the overall project cost. The construction time of conventional concrete batching plants is relatively long, and the initial investment payback period is relatively slow.

In summary, containerized concrete batching stations are superior to traditional conventional batching stations in terms of mobility, production efficiency, environmental performance and cost control, marking the transformation and upgrading of the construction industry. This new batching station not only improves the production quality of concrete, but also helps the construction industry move towards intelligent and green development.

As the construction industry’s requirements for efficiency and environmental protection continue to increase, containerized concrete batching plants will undoubtedly become an important direction for future industry development, leading construction companies to embrace a more efficient and sustainable future.