Electric Motor Powered Concrete Pump

Electric Motor Powered concrete pump is a concrete pumping and transportation equipment, which is widely used in urban construction, bridge construction, power and other energy facilities and other construction projects. This machine is suitable for areas with stable voltage, has low noise during operation and is easy to move.

The working principle of the electric concrete pump is mainly to rely on the motor to drive the hydraulic system, and the hydraulic system pushes the piston or rotor to do reciprocating motion, so as to continuously transport the concrete through the pipeline.

Application scope of Electric Motor Powered Concrete Pumps

Construction sites: including residential buildings, commercial buildings, roads, bridges, etc.

Tunnels and underground projects: such as subway tunnels, underground parking lots, etc.

Water conservancy projects: such as dams, river management, etc.

Other occasions where concrete transportation is required: such as prefabricated component production, concrete pouring, etc.

Different capacity of Electric Motor Powered Concrete Pumps

The specifications and models of motor-powered concrete pumps are usually distinguished according to their production capacity per hour. Common specifications include HBT40, HBT50, HBT60, HBT80, HBT90, etc.

These numbers represent the theoretical maximum production capacity of the mixing plant per hour. The larger the number, the greater the production capacity.

Working process of Electric Motor Powered Concrete Pumps

When the motor drives the trailer pump, the concrete enters the injection port through the hopper and is pressed backward by the screw conveyor on the volumetric hopper. At the same time, under the action of the concrete conveying cylinder, the concrete is pressed into the outlet pipe, and the pressure difference is quickly used to form pumping, realizing transportation from the mixing station to the construction site.

Components of Electric Motor Powered Concrete Pumps

The electric concrete pump is mainly composed of a radiator, a motor, a control system, a hydraulic oil pump, a lubrication system, a sealing system, a mobile frame, a concrete pipe and accessories.

Hopper: used to load concrete.

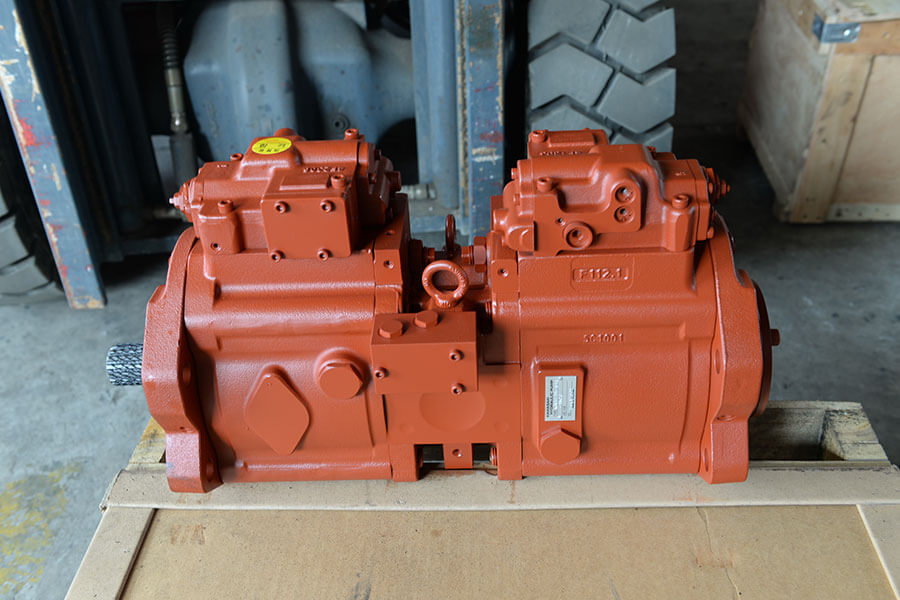

Hydraulic system: including hydraulic pumps, hydraulic cylinders and valves, etc., used to provide power and control.

Concrete cylinder: used to store and transport concrete.

Distribution valve: used to control the suction and discharge of concrete.

Delivery pipe: used to transport concrete to a designated location.

Control system: used to control the pumping process to ensure the accuracy and safety of the operation.

Motor: provides power to drive the hydraulic system.

hopper

Oil Pump

motor

Control system

Advantages of Electric Motor Powered Concrete Pumps

Good environmental performance: Electric concrete pumps are powered by electricity, do not emit exhaust gas, have low noise, and are environmentally friendly.

Low operating cost: Electric drive is cheaper than diesel engine drive and is easy to maintain.

Efficient and stable: Electric concrete pumps can provide stable power output to ensure the continuity and stability of the pumping process.

Wide range of applications: Applicable to various construction sites, including urban construction, rural residential construction, etc.

Easy to maintain: The structure of the electric concrete pump is relatively simple, and maintenance and maintenance are relatively convenient.

Are you ready to start your project?

As a professional construction machinery manufacturer, Henan Hengyuan not only has a professional technical team, but also has excellent machinery quality. The construction machinery equipment produced by Henan Hengyuan welcomes customers from all over the world to purchase.

1.We will recommend the corresponding machine to you according to your production needs.

2.We will calculate the site and factory area according to your production requirements and give you factory construction suggestions.

3.Our professional technical engineers will draw professional installation plans and machine layout drawings for you.

4.If you encounter any problems during production, we will send professional engineers to connect via video or solve them on site.

Get ready to contact us

If you are ready to start your project, please contact us immediately. Tell us your needs and we will provide you with the most suitable production plan and quotation.