Vertical-shaft Planetary Concrete Mixer

Vertical shaft planetary concrete mixer is the core equipment of various civil engineering construction sites and commercial concrete mixing plants, block and prefabricated parts industries.

This series of mixers have both revolution and rotation, complex motion trajectory, strong mixing motion, high efficiency, strong homogeneity, suitable for mixing high-quality concrete.

Application scope of Vertical-shaft Planetary Concrete Mixers

The vertical axis planetary mixer utilizes a high-efficiency, no-dead-angle mixing design. Consequently, it serves a wide range of industries, including refractory materials, ultra-high performance concrete (UHPC), and general cement concrete production. Furthermore, this equipment operates effectively in major construction sectors such as hydropower, highway, port, bridge, and airport projects. Given these capabilities, it stands as an ideal mixing solution for demanding applications.

Different capacity of Vertical-shaft Planetary Concrete Mixers

Vertical-shaft planetary concrete mixers are suitable for various types of mixing tasks. They are usually divided into different models according to their hourly production capacity. Common models include JN500, JN750, JN1000, JN1500, JN1500A, JN2000, JN2500, JN3000, etc.

Working process of Vertical-shaft Planetary Concrete Mixers

The output end of the motor drives the speed reducer to work, and the power generated drives the stirring arm to rotate and the scraper arm to revolve. Therefore, the stirring motion has both revolution and rotation, the stirring motion trajectory is complex, the stirring motion is strong, the efficiency is high, and the stirring quality is uniform.

Components of Vertical-shaft Planetary Concrete Mixer

The vertical shaft planetary mixer is mainly composed of motor, reduction mechanism, transmission mechanism, tank body, slewing bearing, machine base and other components.

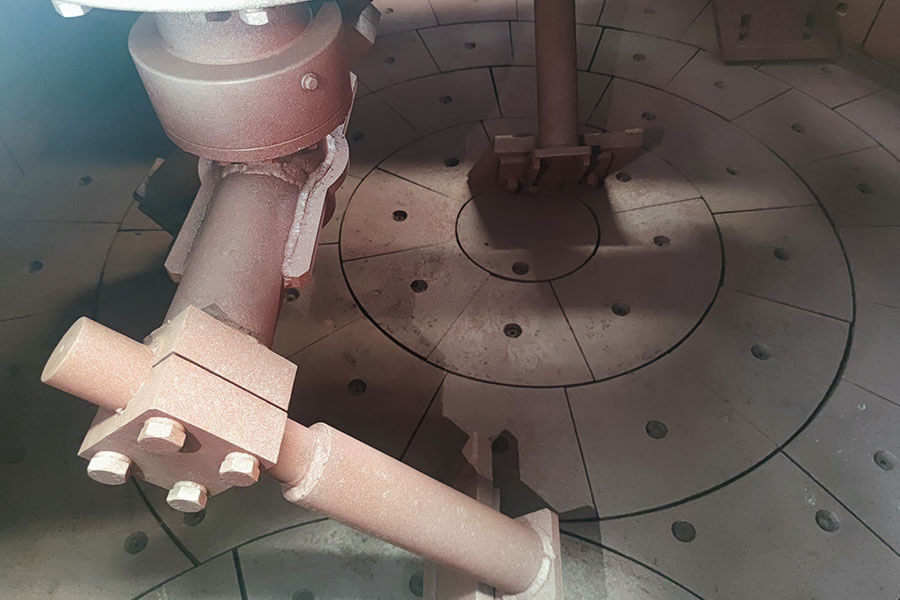

Stirring device: includes stirring arm and stirring blades, usually with two or three stirrers.

Planetary frame: drives the stirring shaft to revolve and rotate.

Scraper: rotates with the planetary frame, continuously scrapes the barrel wall to prevent material retention.

Reducer: adopts a special reducer structure to make the stirring device revolve while rotating.

Transmission device: includes motor and coupling, and drives the stirring device to operate through the reducer.

Machine shell

scraper

motor

Siding

Advantages of Vertical-shaft Planetary Concrete Mixer

The transmission is stable and efficient, and there is no noise during operation.

The mixing is uniform without dead corners, and the materials are mixed evenly.

The mixing range is wide, suitable for mixing and stirring various materials.

It is easy to clean, equipped with high-pressure cleaning device and spiral nozzle.

The structure is simple, the later maintenance cost is low, and the unloading speed is fast.

The sealing performance is good, and there is no risk of leakage.

Are you ready to start your project?

As a professional construction machinery manufacturer, Henan Hengyuan not only has a professional technical team, but also has excellent machinery quality. The construction machinery equipment produced by Henan Hengyuan welcomes customers from all over the world to purchase.

1.We will recommend the corresponding machine to you according to your production needs.

2.We will calculate the site and factory area according to your production requirements and give you factory construction suggestions.

3.Our professional technical engineers will draw professional installation plans and machine layout drawings for you.

4.If you encounter any problems during production, we will send professional engineers to connect via video or solve them on site.

Get ready to contact us

If you are ready to start your project, please contact us immediately. Tell us your needs and we will provide you with the most suitable production plan and quotation.